Archify Connect: Sealing Success - Mastering Construction Sealants with Bostik Seal n' Flex

Archify Connect is our web series that responds to the increasing demand for virtual learning and networking. Our latest session was held on the 16th of November 2023 and was presented by Bostik. Below is a transcript of the presentation.

Our topic today will be Seal n' Flex by Bostik.

Despite a global company called Arkema back in 2015, where their largest adhesives have been seen in division under the Arkema banner, proudly, I'm happy to kind of report that 60% of our products are manufactured here in Australia, which is a really nice feather in our cap. And that includes the Seal n' Flex range of polyurethanes that we're going to be talking about today. You can see on the right-hand side there, are just some of our distribution centres, and a p user made where I'm located in Thomastown, in Victoria.

So, if we start at the very beginning before we get into the nuts and bolts, what is the ceiling, you know, they're pretty nondescript products, they just sit there in a cartridge or in a sausage on the side, and sometimes a lot of technology in there. Quite often they're kind of just, you know, left to the guy on the tool to make a decision, but they play really integral, integral role in the construction and can actually beat the cherry on the top and if they perform correctly, you're designed to succeed. So the way that we view a scene within Bostik is a flexible material. When applied between two or more parts of a structure, they prevent elements like air, moisture water and dust from penetrating that joint due to due to the adhesive qualities. And importantly, the ability to accommodate differential movement, remember really is the key and different products will move and contract and expand at different rates. It's important they're installed correctly, but if they are installed correctly, the movement will really be the foundation that every other requirement is built upon.

Why do we use joint sealants? Again, to defer it to accommodate differential movement of building materials, it's not always concrete to concrete, it could be concrete to say aluminium, it could be timber to masonry, lots of different substrates to consider. They are used to dampen vibrations and minimize sound transmission as part of an overall wall assembly, particularly your acoustic walls between rooms, waterproofing and there's a weathering steel with a sealant on the facade between aluminium panels, and also they're integral to the waterproofing system. So if any of you have ever nominated a waterproofing system, more often than not a sealant is used as their bond breaker in the corners, particularly with class three membranes. And it's important that that meant that the system that will that sealant is compatible with the membrane that's going over the top. passive fire protection is a big space for sealants. They're often used to seal gaps and penetrations in fire-rated walls. Anti-pick treatments to two prisons in holding sales and mental health facilities quite often, a regular sealant isn't durable enough or doesn't cure hard enough to stop being picked out essentially. So certain products cure slightly higher so they can be deemed as being not pick resistant. Structural bonding as well some sealants wear two hats, and they are used to bond as well as seal stiffeners. On the back of cladding panels, again is another example. And they sometimes use just simply sealing a gap. Some Sealants are just water-based acrylics, they have limited movement because they're used internally where you've got a constant temperature. And they just used to say seal your skirting board. For example, before you paint a wall, it's not always overly technical. Sometimes it's that simple.

So why there are so many options these are some of the terms I've heard over the journey. I call everything silicone came from a Victorian-based architect; I've got some of the some in the back of the van is a term that he's just got disaster written all over it. If you use something in the back of the van, the chance of it being compatible with the sealant or the primer that's also being used is pretty slim. Always go for a single point of supply, and Bostik. Fortunately, I have the associated primers to accommodate a range of substrates to support our sealants and help them succeed.

Different joints have different requirements, and this is the reason we have so many options, again, movement capability, you know, is it an aluminium facade where the joints are going to be quite, you know, opening and closing pretty high rates? What kind of adhesion do we need to achieve here, it needs to be a high modulus or stiff is chemical resistance and is it going to be exposed to UV as a long list of requirements there. And those images just kind of paint a bit of a picture, you know, you've got a joint in the bottom right there where you've got industrial traffic and over the top is a ceiling, you know, durable enough to withstand abrasion by trucks by pallets, you know, there's a number of things to consider, which is why people like myself exist to kind of work those work through those hurdles nice and early.

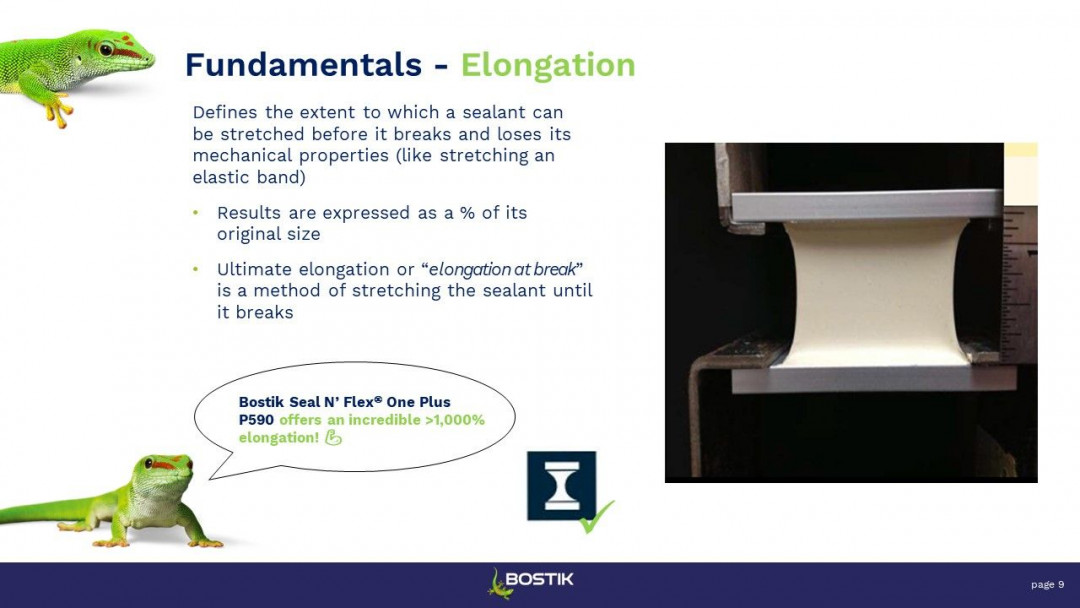

So, one of the things we'll look at, particularly with sealants, is we want to get we're going to identify characteristics that kind of align themselves with our requirements. And when you see a product which is a low modulus or high levels of elongation, instantly that the product is pretty elastic, and therefore it's going to accommodate lots of movement. It will be soft, but it only it will only accommodate good amounts of movement. So, when we talk about elongation, we're looking at the extent to which the sealant can be stretched before it breaks. Imagine that elastic band, for example, you get to that point where it's, you know, it's just about to go. So, we stretch it, and we represent the results as a percentage of the original size. So, if it started off at, say 10 centimetres and we stretched it to 100, then that will be, I'm not going to mess but we represent that in terms of percentage. Ultimately, elongation or elongation of break is essentially just taking it to the point at which it snaps. And again, we will then represent that within the TDS just to provide some guidance as to how elastic the product is.

Proud to say that Bostik Seal n’ Flex One Plus P590, which is one of the products I'll expand upon towards the end of the presentation offers over 1,000% elongation.

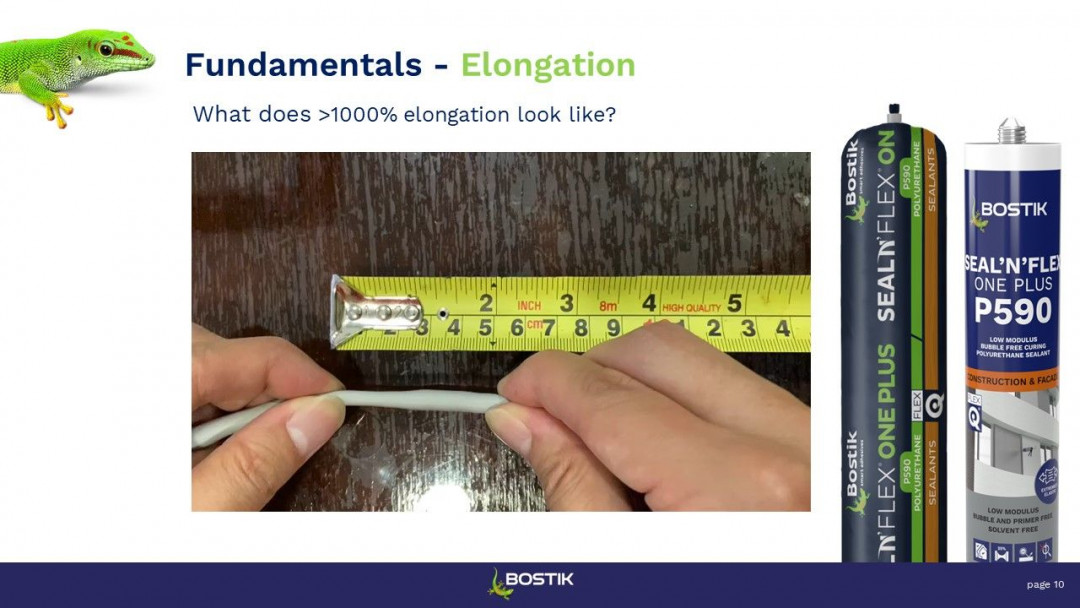

And you can see that here in this video where they've taken the original sample, and it stretches out almost 567 times its original length. But the important thing to consider is the way it recovers a lot of sealants, acrylics are one technology, you can stretch it, but the chances of it recovering back to its original size are pretty slim. With the Seal n' Flex P590 you've got that peace of mind that if for any particular reason, there's a sudden move and the joint opens up, you've got the peace of mind that it's going to it's going to recover again. And that joint of those seals is going to be maintained.

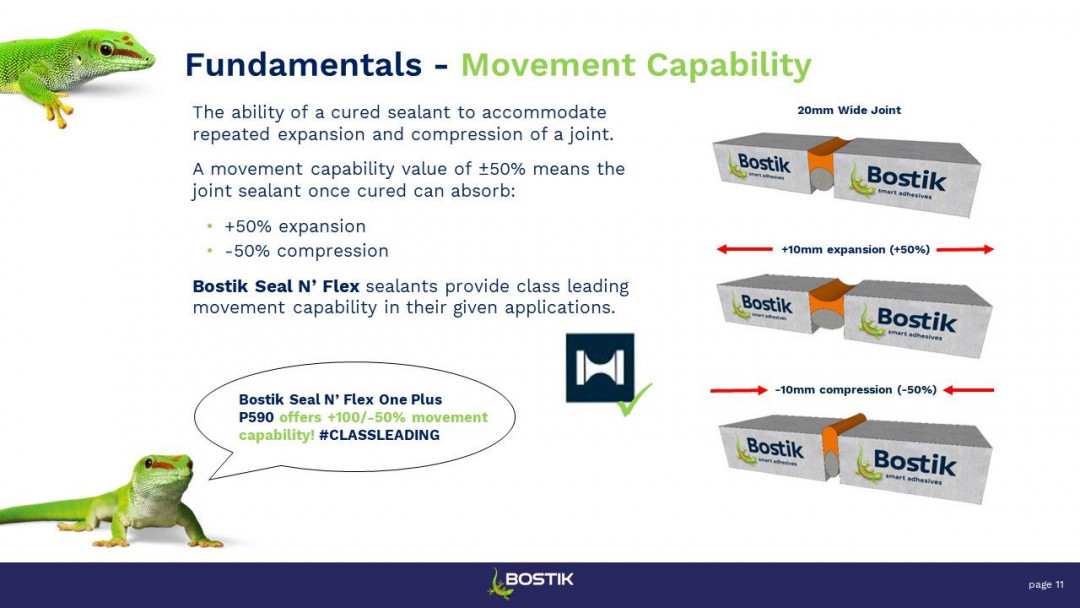

Brings us on nicely to movement capability. So, when we talk about movement capability, what we're what we're discussing here is the ability of the cured sealant to accommodate repeated expansion and contraction of a joint. Now it's important here that the sealant is installed correctly. And we'll get to that in subsequent slides. But when installed as per our guidelines, if we've seen it will come with a nomination, I stated movement capability. So here for liquid for example, I've used plus or minus 50%, I can just grab my laser pointer here, you can see here plus or minus 50%. What that actually represents is that the sealant wants it installed correctly, and can absorb 50% expansion and 50% compression of its original size. So, looking at the images on the right-hand side, if you've got a 2020 mil white joint 50% of that will be 10mil so you can expect to withstand 1010, an additional 10 millimetres expansion and timber and timber compression. So, 20 millimetres will compress down to 10 and expand out to 30. So, there's a lot of movement and so more than more than capable of withstanding most movement on most joints. But we can actually go one better than that with the scene and flex the P 590. Again, that's been tested and certified has been able to withstand a plus 100 minus 50% lumen capability. So, if it's installed at 20, it will actually expand out to 40, sort of double its size 100% and compress 50%. The reason we don't go plus 100 minus 100 is if you went to minus 100, you just squeezed the product completely out of the joint the two substrates would touch. So plus 100 minus 50 is the highest classification you can achieve and proud to say the Seal N’ Flex One Plus P590 achieves that.

UV resistance is another requirement as well. So, UV is very obviously a huge requirement in Australia. And what we're looking at here is the ability of the sealant to resist exposure to UV light and sunlight. So, sunlight being what we can see UV light in other parts of the light spectrum we can't see but we'll still attack a product if it's not resistant to UV. So, as you can see some examples on the right-hand side there was a product that started to discolour chalk breakdown, if not resistant, but graph to say that the Bostik seen or flex products have been stamped with Visa, these little icons here which kind of just demonstrates and confirms that they're suitable for use in UV exposed applications that can be used confidently, externally as well as internal.

Paintability is a requirement quite often a joint will be designed and installed with a plan to apply a coating over the top. Applying a coating is often a bit you know, not ideal because not always paint for example, an acrylic external acrylic paint doesn't have the necessary elastic properties that the sealant would. So quite often you'll see paint applied and the paint might be crazed or split down the centre. And that's simply due to the fact that the paint doesn't have the movement accommodation. But if you do need to paint the ceiling, most sealants can be painted and the ceiling flex range can be painted also. So, polyurethane hybrids and acrylics can all be painted. We always recommend doing a test where possible just to determine that there are going to be no foreseeable sort of incompatibility issues. But just something to note as well, like a little FYI, silicone sealants can't be painted. I've only done if you've ever tried this at home when you're doing some DIY but it's just simply down to the fact that they've got a low surface energy, they're particularly they're very, very smooth and there's just not enough meat there for the paint to grab on to so if you do need to paint a joint, steer away from it I'm still waiting on silicones.

And then joint design, which is a real key area that I want to focus on. And it really is critical to the success of the sealant performing. So, if you're doing the research and you're looking at Bostik Seal N’ Flex, I highly recommend looking at the technical datasheet it just ensures that your joint requirements and the intentions are aligned with our recommendations and the characteristics of the products stated on the data sheet. Because you will obviously want to work within the realms of the datasheet, you can try and stretch them in some areas. But if you do often, that leads to disaster. And there's an example here where applying a joint sealant in a joint two wide. This is a silicone from our range, which usually we say we recommend is installed up to 14 millimetres. This is an example where we had the guys in the lab install a joint of 17 millimetres. And as you can see, as a result of not having enough body to span that joint, it starts to slump, which is completely fine in a lab, you know, we can tidy that up, throw out the samples and start again. But this is a facade and you've tried to spend a joint and the seed and can't quite get there, all of a sudden, you've got liquid silicone that needs to be removed, and it'll be it will be a nightmare. So always work within the realms of the TDS. Alternatively, look at other technologies as well, because of what we can offer with the Seal N’ Flex One Plus P590. It can actually be used in joints up to 80 millimetres wide vertically, which is a real game changer. Horizontally, you know, different story, you know, gravity doesn't take as hold as much. But it's just an example here. And this sample here is the P590. It's been installed in an 80-millimetre-wide joint. And this is six hours after it's been installed. So, six hours, six hours into the cure vertical. And there's actually no slump occurring there. So that's peace of mind. But if you do come across a scenario where you've got joints slightly out of the ordinary and a little bit wider, contact us we've got a solution for you.

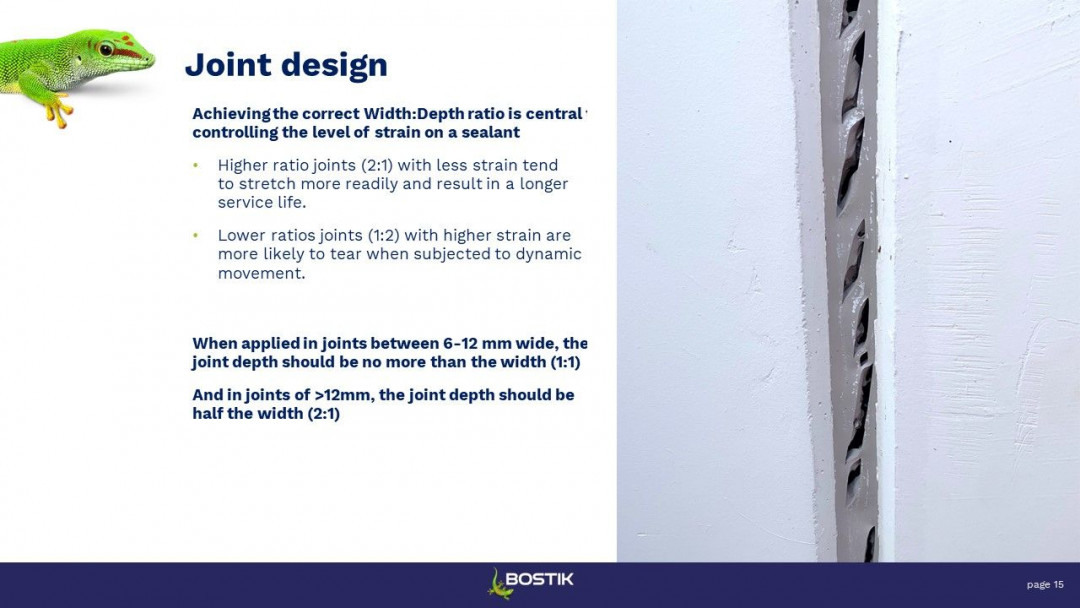

Just on joint design as well. But I just want to stress that it's really important for the sealants to ensure that we achieve the correct ratios in the width and the depth. Typical joints work to a two-to-one ratio. And what we mean by that is that the width is double the depth. So, as you can see on this, here in this detail, that will allow the sealant to expand and contract and keep the strain on the substrate or the bond line lobe. Quite often we'll see a train of thought that if you put apply more product into the joint, you're going to get a better outcome, where in fact, it's actually the reverse. The deeper the product goes, the less elastic it becomes, you essentially end up with a block of rubber. And you can see here where they've reversed it where the depth is double the width. And you can see the level of strain on these joints has gone up to 94% and 250% on compression. So, we recommend anywhere between six to 12 millimetres of work to a one-to-one ratio. So, if your joint is 10 mil wide work to 10 mil deep. If you go above 12 millimetres and you've got a 20-millimetre-wide join, you want to work to the two-to-one ratio, you want to aim to get a 10 mil deep joint and just want to share a bit just a project that we went through recently. It might be small on your screen, but what you can see here is delamination from one side of the joint and we knew what this was straightaway. We it's destructive testing, we took out a section and measured the width and the depth. And lo and behold the depth of the sealant as you can see was deeper than the width of the joint. So we knew straight away that it was just an installation issue. And that can be rectified by getting the backing rod to the correct depth and achieving a good seal. And this is what you want to achieve a nice two-to-one ratio concave join. And yeah, you'll get many years of service out of your ceiling. Although you do come across some anomalies like this, which you know, the ceiling won't be able to withstand subsidence. So, I'll just throw that in there just to say you know, there's always something new around the corner.

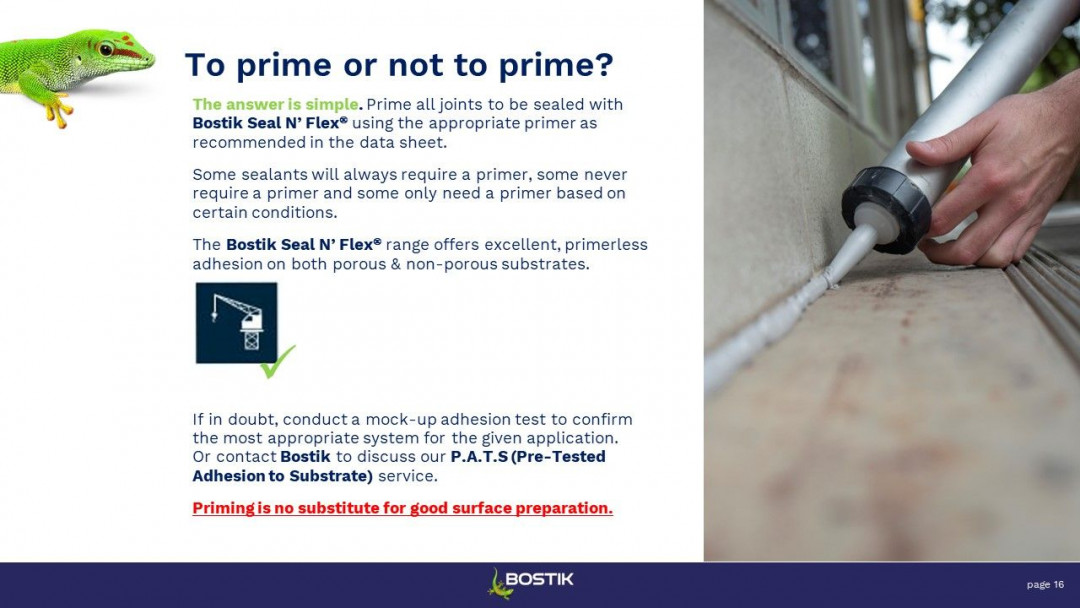

When it comes to providing you know this priming joint seal when you're sealing with Bostik Seal n’ Flex we recommend following the TDs and prime using the primer recommended in our guidance documents. Some seals will always require primers, and some you know will only need to meet certain conditions. Proud to say the sealant flex range offers excellent adhesion to a range of substrates prior to this. There's no denying that using a primer will improve adhesion. But in most scenarios, most cases a prime is not required. But if in any doubt, when you're on-site or when you read the contract or you're doing a walk around and you've got some question marks, conduct a little test on site you know just do the gun come out on the wall do appeal test, we can help advise as you achieve that. Alternatively, and this is something we do quite regularly Bostik offer a service called packs which is pretested adhesion to substrate. We've done this on numerous projects to determine the best method of achieving adhesion onto certain substrates. And it's just an example on the right-hand side here where we used for our fire band one which is a fire-rated polyurethane onto that aluminium mullion from a facade. And so, we did the peal tests and we submitted the findings. So, we can assist whenever there are any question marks in regards to adhesion. Little note down the bottom there, priming is no substitute for good surface prep. So, in terms of joints, you want to make sure the joints are nice and clean dust dust-free any mortar has been removed before you apply the sealant.

Then just a large section here on troubleshooting some of the common issues that we see around the inner market.

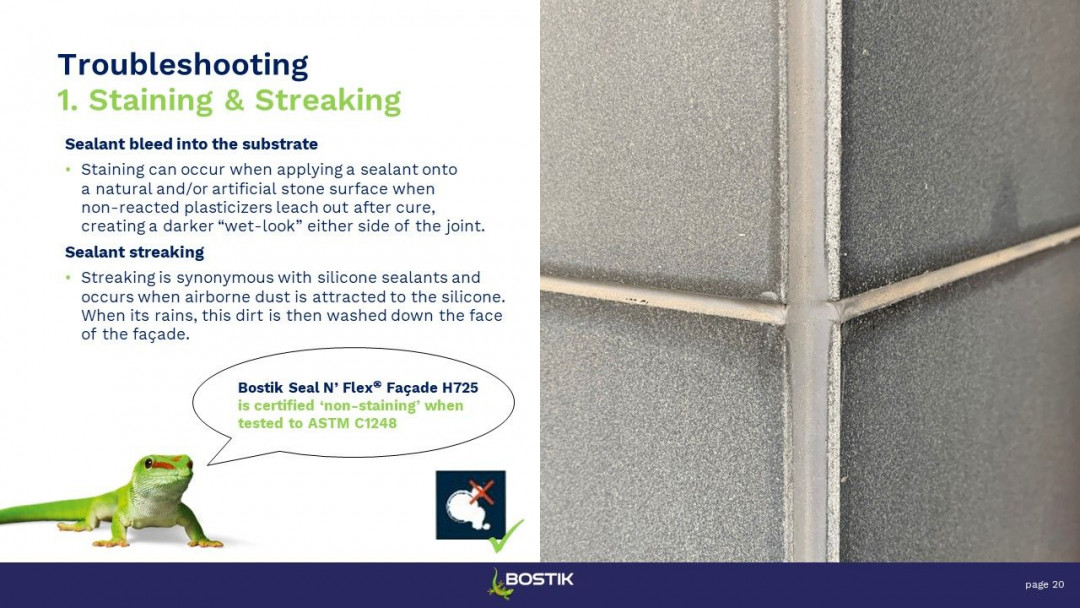

So, we see this a lot on street staining, particularly on stone facades, so you've got natural stone, artificial stone. And what this, what this is, is a nonreactive plasticizer in a sealant. So, a sealant is made up of several components, one of them being a plasticizer, and an oil, which will make it workable and easy to apply. In this instance, once the sealants are cured, and there might be some leftover plasticizer, now that's got nowhere to go, the sealant is used what it wanted to use, and he's got nowhere to go but out. And being a porous substrate, It just soaks it up like a sponge. So, as you can see, on this facade here, it's just soaked up that plasticizer. And you get that darkening on either side of the joint. And I guarantee after this presentation, you will be walking around and you'll be seeing staining everywhere. I'm forever taking pictures myself, but regardless of the type of stone, it will still have an effect. And so, the way to overcome that is to use products, which are deemed as being non stain non-staining, when tested to the relevant standards for non-staining. Or do some testing in advance. You know, if there's a particular product, you're looking to specify, do some testing in advance, there are methods that we can assist with, and that will determine whether or not you're going to have an issue down the track. streaking is kind of a similar problem but on non-porous surfaces. So, if you imagine the stone will absorb the plasticizer on a non-porous surface, it can’t absorb it, therefore it runs down, and it will actually run down the facade. And silicones, for example, are more of aesthetic charges and other technology, so they attract a lot of dust. And when it rains, that that dirt gets washed down with the current of the facade, as you can see here. Now this looks quite severe because quite a light facade panel has been used. But essentially, this is the migration of plasticizers down the facade, which is attracting dust. So, I guess to overcome this, consider options like the Bostik Seal N’ Flex Façade, which is our hybrid sealant, and the H725, which is certified as being non-staining, it can be used on these types of surfaces. And you won't have any issues with staining, it comes with the relevant testing. So just something to consider, if long the longevity of the facade and the overall look and feel, which is a concern.

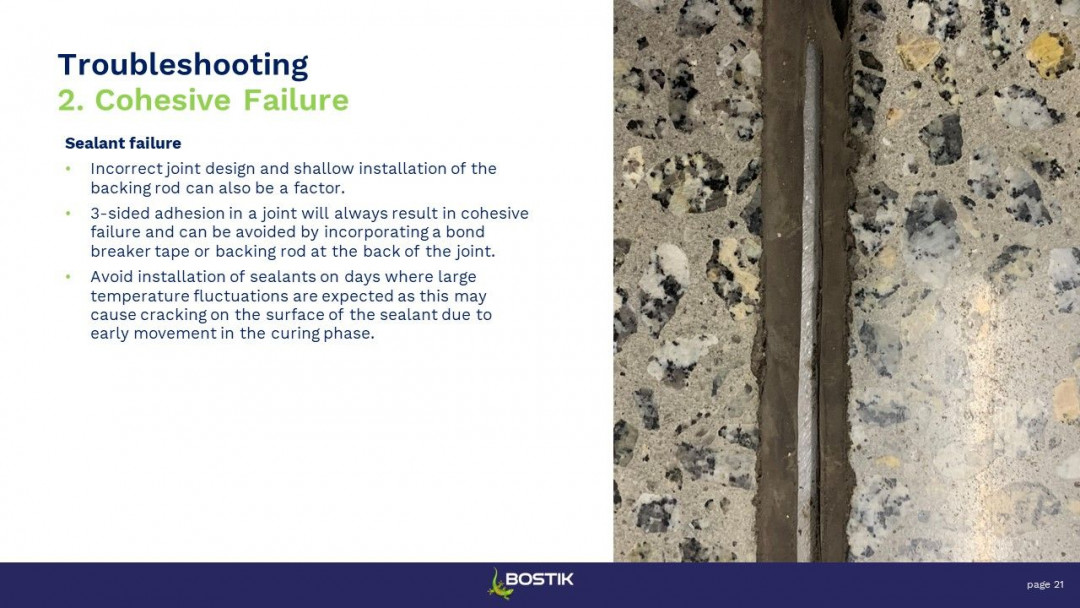

Because Cohesive failure is a big one. And we see this a lot as well. And this really comes down to installation and design. In this particular instance, the backing rod wasn't installed deep enough so that the Senate was too thin. So, when that joint opens up when the slab moves, there's just not enough strength there. And it just splits down the centre. three-sided adhesion can cause cohesive failure as well, cohesive failures are split down the middle where the sealant is bonded to the side and the back, so therefore it can't move which often results in a split. And sometimes what can happen on warmer days when a seal has just been installed on a facade is, is early movement and cracking or, you know, cohesive failure in the surface. So, it gets installed at a cold point of the day, it's a warm point of the day. And then overnight, the surfaces cooled down, the joint opens up because everything can track if the same has just been installed, and it's not cured enough or not strong enough, it just splits on the surface where it has cured, and you get this cracking. And so that's just a case of just understanding the environment, the climate, and just applying the scene at the correct time.

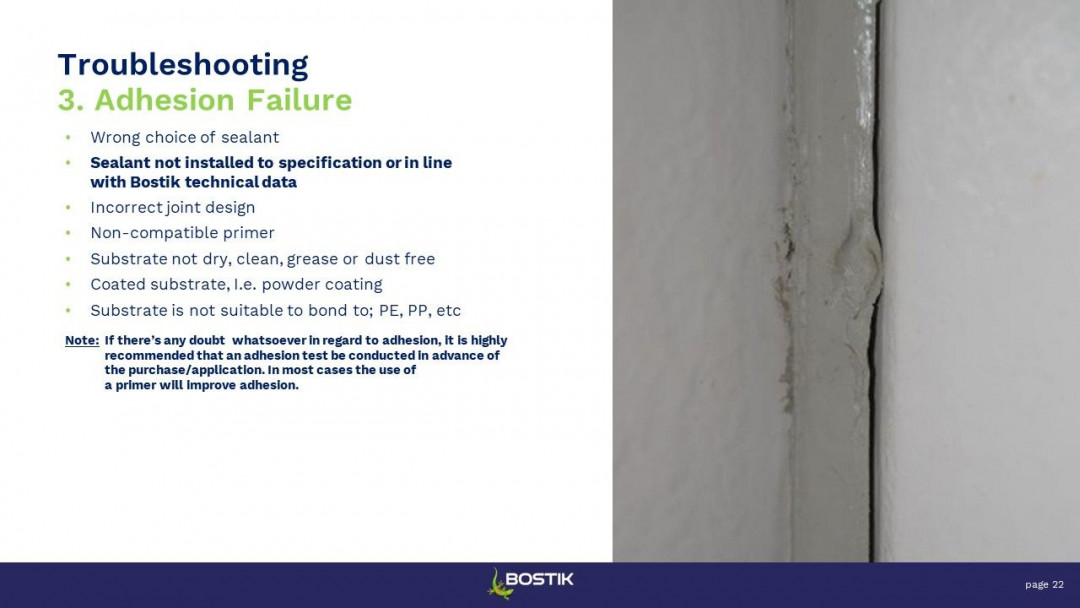

Adhesion failure has a number of reasons that can occur the wrong choice of ceiling and ceiling not installed as per guidelines. As we saw earlier joint design and depth in this particular instance, it was a non-compatible primer. Going back to the earlier slide, the contractor on this particular project used a primer from a previous job that you had in the back of the van assuming that the primer would work universally, but that wasn't the case. Therefore, we had to go back we do some testing, we went back with their own priming system, and they used the scene and flex system just to just to improve upon what was a failed joint. But again, if there are any doubts whatsoever, contact us and we can help you determine the most suitable route to achieving adhesion against a particular substrate.

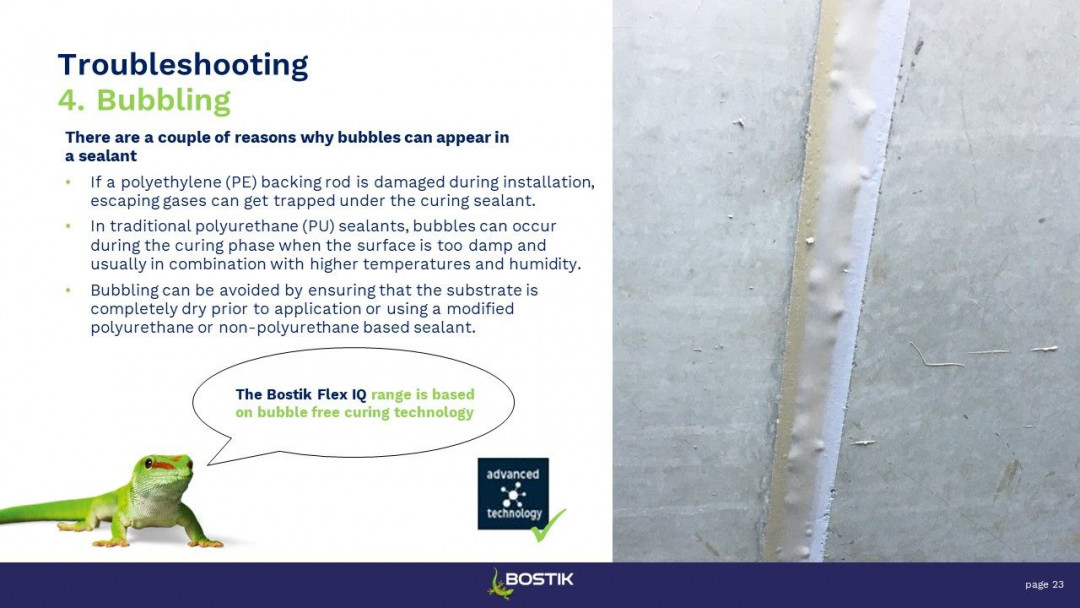

And then lastly, bubbling. This is synonymous with warmer, more humid environments. And there are a couple of reasons why bubbling can occur. One. The first one is when you're using backing rods, sometimes that backing boards get damaged, and they can outgas when it warms up but that's less likely than the second reason traditional polyurethanes cure with moisture. And when they cure the moisture, they create CO2 gas. In a humid environment, they will cure quicker and they skin over and that gas gets trapped. It's got nowhere to go. And what happens is you get this speckling on the surface where the bubbles are trapped within the sealant. And that will be through the depth of the sealant. So, again, with the new Bostik range, our new polyurethanes are based on non-bubbling technology so bubbling for us is a thing of the past and is kind of associated with older technology, older, more secure technology, we've got new technology in our polyurethanes, which guarantees they're not going to bubble. So, you can use them on damp substrates, you can use them up to sort of 99% relative humidity, who cares, it's not going to affect the product, you can knock yourself out and just apply lineal meters per days, it's not going to it's never going to bubble.

And then lastly, I just want to give a bit of an introduction to Seal n’ Flex. I've touched on a couple of products during the presentation, but just going to expand on these particular products which are relatively new to the range and they kind of fit into certain niches.

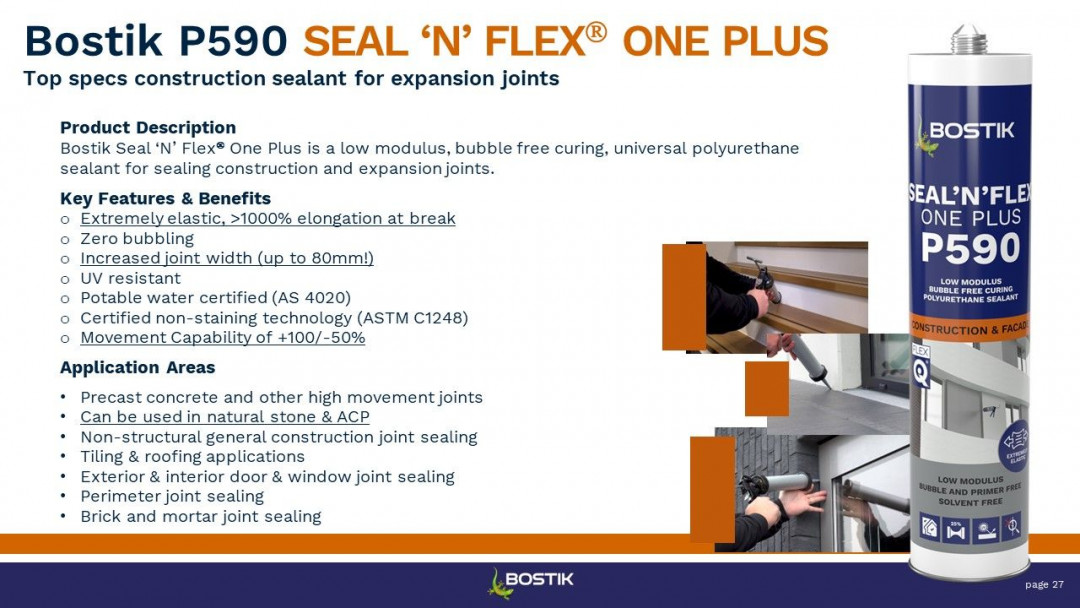

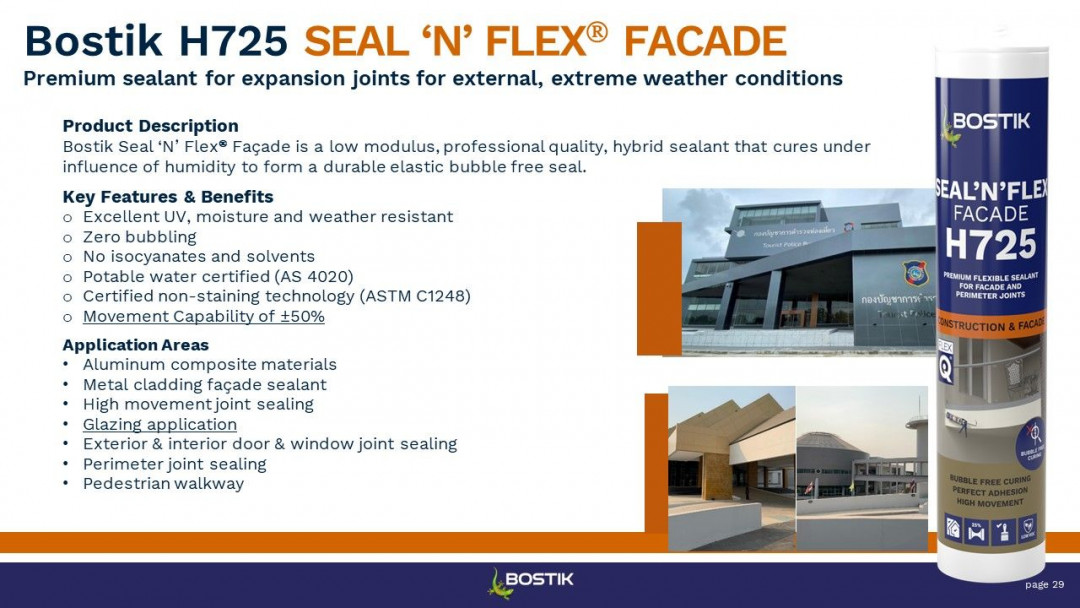

So, we've got the Seal n’ Flex P590. And this is as in terms of this, the abilities of the product, this is very, very high performance. This is the one that offers the plus 100 minus 50 movement accommodation. So, if you've got joints, that are quite volatile and exhibit lots of movement, this is definitely the go-to. The Seal n’ Flex Premium, the P795, is extremely durable, it's a high-modulus product, and it's trafficable. It comes with fuel resistance, and, and is very, I guess resistant to a number of chemicals and instances of abrasion that you find in floors and industrial applications. And then lastly, you've got the Seal n’ Flex facade, which is our hybrid and the hybrid is great for those kinds of external facade applications, or weather conditions, you know, sun, rain, wind, sleet is the go-to and extremely good adhesion to those typical substrates that you often find on a facade.

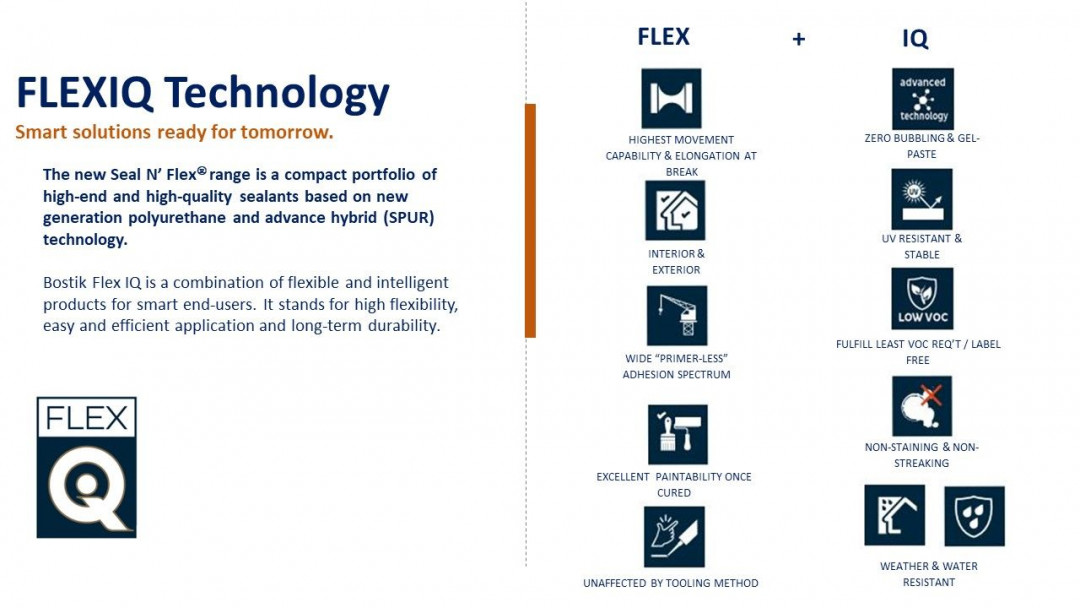

In regards to the technology itself, you would have seen all these icons as we go through. But again, this is really just kind of taking the best of what Bostik has to offer, and just putting them into a range. So Flex IQ is what we call it. And the Flex is really the, the, I guess the advantages that it offers you in terms of movement or movement, accommodation, you know, UV resistance, primal adhesion patentability, but then the IQs really gotta guess, where we've kind of, you know, flex our muscles a bit and introduce a real game-changing technology like the zero bubbling, the high levels of UV resistance, GPUs and hybrids, you know, the lowest VOCs and non-staining testing. So, I guess it's just a peace of mind solution that we can offer as a suite of products to consider for your next for your next project.

So just a bit of detail just to kind of expand on each of the products. So, the Seal N’ Flex One Plus P590, really supersedes the older Seal n’ Flex one that we've had in our range for many, many years, which is a more secured PDU. This is a step up in terms of performance and, and just offers all the benefits that Seal n’ Flex while never quite offered. So again, I won't go through this in much detail because we've touched on it before, but we've got the 100,000% elongation, which again, reduces the strain on the joints, it just promotes longevity, zero bubbling, as you saw before, 80 mil wide joints, UV resistant is potable water certified. So, in and around drinking water is fine to use. It's non-staining to ASTM C1248. So again, it's good to be using natural stone, and again, that movement capability. So, here's a list of applications where it can be used, but typically, high-movement joints are where this product is considered.

When we move to the Seal n’ Flex premium. This is a high-modulus product, so it's slightly harder. It can accept traffic, vehicular traffic, and foot traffic, there's a slight requirement when detailing for vehicle traffic like a bit of a recess in the application, but great for those kinds of hard stands in sort of truck yards for example, car parks, those kinds of applications, but highly elastic again, zero bubbling, again, potable water certified and certified non-staining, where this product really stands out from the range that it actually has fuel resistance testing to be S5212. So, if anyone is documenting service stations or say industrial applications where there might be fuel storage, this is a really good option. And there are a couple of images there from a truck stand and a fuel terminal in South Australia.

And the Seal n’ Flex facade again which is our hybrid, slightly different technology to polyurethane our hybrid technology. Excellent UV resistance is great for those facade applications very great. No isocyanate, no solvents, potable water certified non-staining, again, ticks all the boxes and is a great option for those for solid applications.

So just before I sign off, I'm just conscious of time and want to keep it to the half hour so why Bostik? What you're what can we offer you? What was the point of the difference?

So, I guess we weren't by the mantra, you know we make it stick and you get the glory, we are very much unseen in what we do. However, we're kind of integral to the success of the products around us and your case, your visions and your design. So, we'd go from quite very much work to a total systems approach, we won't just offer a sealant, we will consider what's around it and offer you the primer will offer you to maybe the Finishing System or the associated products just to make sure you've got a single point of supply. And that compatibility chain is maintained. We can do project-specific solutions. So, specification writing is what I do. And we can provide that in any format, you need just to make sure that that's captured and taken through the building process. I mentioned the PATs program that we ran through the pre-tested adhesion, there's something we do daily through our technical and R&D teams just to give you that peace of mind on-site training, as you can see here, in that particular instance, we're bonding some acoustic panels to a soffit technical presentation site inspection. We can support you with testing or any R&D queries that you might have. And then lastly, this is just a snippet of what we have to offer in terms of education for the architectural design community. We want to create Formal CPDs - we can expand on these topics if that's of interest.

And then again, just scratching the surface really of what Bostik had to offer. Sealing and bonding is one area. We specialise in fire-rated as well; we have some glazing silicones. But we obviously expanded to waterproofing and tiling soft flooring, and Hardwood Floor Leveling adhesives. And then we got some more structural products towards the end of our range, structural grout and concrete repair. So, we're very much a broad supply of construction building products. But again, we always bring them together and make sure everything's kind of compatible and you've got a system that you can trust and that you're confident in documenting.

So, I guess that's it for further this snapshot of specifying ceilings and ceilings success we've seen a flex so look happy to open the floor to any questions that you guys might have.

Indonesia

Indonesia

New Zealand

New Zealand

Philippines

Philippines

Hongkong

Hongkong

Singapore

Singapore

Malaysia

Malaysia