Archify Connect: Don't Risk It. Dampfix® It.

Archify Live is our web series that responds to the increasing demand for virtual learning and networking. Our latest session was held on the 5th of April 2023 and was presented by Bostik. Below is a transcript of the presentation.

Our topic today will be don't risk it, Dampfix® it. You'll see where the Dampfix® comes from as we move through the slides.

So, my name is Dean Carter, I may have dealt with some of you in the past I've been in and around the architectural space for many years now over 11 years in Australia, originally from London back in England, I'm the national specification manager for Bostik so I kind of assist our team and architects and specifiers with finding suitable solutions for a range of applications, not just waterproofing and tiling, but obviously sealing and bonding systems plays a huge role in the Bostik, Bostik world as well as Timber Flooring, industrial flooring, so on and so forth. So very much a point of contact for the architectural sector when trying to find solutions.

So what I'll be sharing with you today is a bit of a soft introduction to Bostik and our Dampfix®, waterproofing range. It's a commonly used product, popular in the commercial waterproofing space. And what I want to try and do today is just share some of those insights with you and get you thinking about the Dampfix®. For any projects that might come along moving forward. We'll touch on priming and why that's such an essential part of the system. Obviously, the membrane does a lot of work. But without the primer, you kind of have not reached the potential of the waterproofing system. And beyond that, we'll look at the priming systems available within our range and the various substrates and situations that they can assist with when we're looking at a various situation.

We'll touch on the Dampfix® range, and will also just focus on Dampfix® Platinum, which is probably one of the newest products in our range and opened up a new channel for us it's very high-performing products. And as the slogan says, it can kind of do everything and as we go through those slides, you'll see what we mean there. At the end of the seminar, we'll just touch on some of the standards that apply them waterproofing, obviously as the supplier will provide you with all their information but we've always got one eye on the relevant standards, whether it be internal or external in conjunction with the NCC, as well as our own guidance from other suppliers.

So, a bit about Bostik and who we are so always get the question, when was Bostik founded? It was founded back in 1889. In the US out of Chelsea, Massachusetts, we originally called the Boston Blacking Company, you can kind of see the time of Bostik. They were established in Australia in 1915 so we proudly have been in Australia for over 110 years now. Products were launched under the plastic brand in the 40s and we took on the company name in the 60s, our Arkema, which is a French chemical, global manufacturing company that bought Bostik and tube they are isn't a big thing. And they're kind of premium go-to in terms of the adhesive space now, so we're proud to share that over 60% of our products are made locally, some of which you will know, some of which you may not know. Bostik 99% of the time we're known for blue tack and blue sticks, which is fantastic because most of my customers use this at prep school, or when sticking up posters and drawings in their offices, but we are still gluing things together but in a more professional sense, we're using sealants to bond precast panels using membranes and taller adhesives in waterproofing applications are very much a go-to local supplier of adhesives. I'm proud to say that all the Dampfix® range is made locally as well. So in Thomas town in Victoria, that complete range of Bostik Dampfix® membranes are produced.

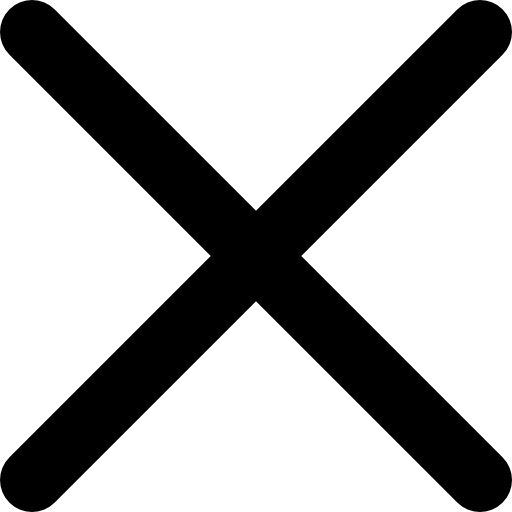

So a bit of history on Dampfix® and where they originated from. So the depth of its brand was originally trademarked in 2004. So it's been around for many, many years. It came with the ASA brand, which Bostik purchased and it's been part of the Bostik family for a while now. And we started to transition away from ASA back in 2018. As a result that came with a complete rebrand under the Bostik banner. And as you can see, that's kind of where we are today we've got a fantastic range under the Bostik banner, you can see there's a really kind of fresh vibrant range. But the most important thing is that they perform, they can look good on the shelf, on-site, or on the palette but they need to perform and what we've got in the damage range now is a complete set of products that tick all the boxes, internal applications external above ground, below ground potable water, positive waterproofing negative waterproofing, we can take almost all boxes with a Dampfix® range.

As you can see, that's kind of where we are today we've got a fantastic range under the Bostik banner, you can see there's a really kind of fresh vibrant range. But the most important thing is that they perform, they can look good on the shelf, on-site, or on the palette but they need to perform and what we've got in the damage range now is a complete set of products that tick all the boxes, internal applications, external, above ground, below ground potable water, positive waterproofing, negative waterproofing, we can take almost all boxes with a Dampfix® range.

Before we get into that there are some things we need to kind of consider, before we start looking at waterproof being some really important points in consideration.

We need to kind of understand why membranes fail because understanding that will put importance on the other causes of both failures. Referring to some of the inflammation that has been put together by the AIW, which is the Australian Institute of Waterproofing, the single biggest cause of waterproofing failures is workmanship, and that can account for a number of elements prior to the waterproofing being installed. It could be ensuring you've got the correct fall whether that's in your primary substrate, or your secondary substrate, not shedding water first. I mean, essentially, waterproofing is a secondary level of protection. If you've got water shedding happening, first of all, then you're not relying on the membrane gravity is doing most of the work. And then if that fails, then then the membrane comes into play. But again, if you're not getting your balls correct, then that can have negative effects in some applications with continuous water loading.

We want the surface to be smooth and clean and free of dust. And that's essential particularly when trying to bond a liquid membrane to a surface if it's not smooth. When you've got undulations in the surface when you apply the membrane, it can cause some thinning out of the membrane, which could potentially lead to pay down the tracks, it's really key that there's a keen eye on that surface and that is prepped adequately. And you want to make sure it's clean and free of any contamination. Easier said than done on a drawing. Everything's nice and it's black and white blacks clean. But in a commercial situation, obviously, there are multiple trades walking backwards and forwards over in errands to be waterproof. Lots of Osprey say from paint, or from maybe some water from some repairs that might be happening.

So, it's really key that those are those contaminants are removed before waterproofing just to ensure a suitable bond is achieved. And sometimes we see no priming or using the incorrect primer. We'll touch on priming in a bit more detail in a second. But no priming, you're relying on the membrane to bind to maybe a dusty surface, which is not what we want. And that can quickly get bound out, off down or the job recently where there was a bit of an air pocket. And when that was popped, the membrane just came off like a wrapper on a Mars bar. It was super easy because there was no primer. You can try and cut corners and save a cost on the insulation but sooner or later, you'll get found out. Also using incorrect primers you may think that the same prime can be used for a wide range of membranes, but more often than not, there's incompatibility and you'll find that out by you'll get delamination essentially. So, it's critical that you use the primer as recommended by the manufacturer.

Membrane selection then comes into play once everything's gone have ready to go. What are we up against? You know, what are we looking to do? Or what area are we looking at? Are we below ground? You know, what's the environment or environmental factors that we're up against? And that will then determine the type of membrane you choose, you know, will it be exposed to traffic UV? If not, if it's protected, then it kind of opens the range of membranes up. So lots of questions to be asked, which is why people like myself exist, because we can ask those questions for you. And then it really can't stress enough beyond the priming, this is the detailing, where you've got a floor meeting a wall, and there's a movement joint, there was a junction, dating back detailing that correctly, in line with the class of membrane really is essential and, TDS from the manufacturer will always provide guidance on the suitable detailing requirements based on the class of membrane, which can either be Class One, Two, or Three. Class One is the least elastic, and Class Three is highly elastic and that will determine how you get you to tell them in playing in those junctions.

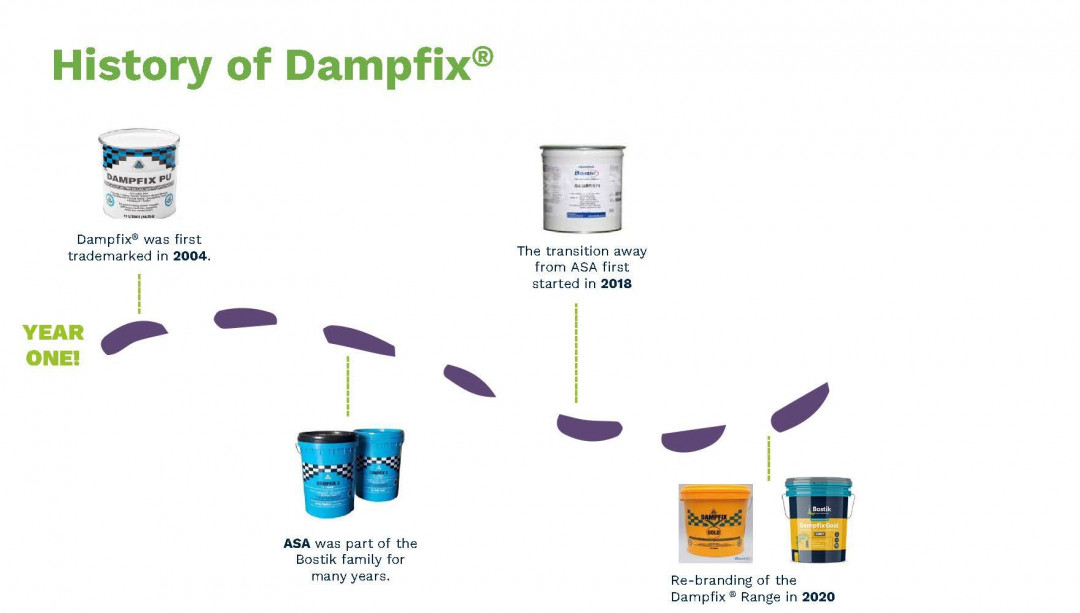

But starting off with primers, just to kind of provide a bit of an insight into what they actually are and the role they play. So a primer is essentially a liquid or pasty product that is applied to the prepared clean substrate. What it does it preps it to that we achieve optimal adhesion, which will then, in turn, provide a performance of the membrane without priming, you're not going to get the best out of the membrane are a number of reasons.

You want to select the primer based on the substrate type. There are porous substrates like masonry, concrete, and FCC, for example, as well as non-porous substrates like PVC, black PVC outlets, or aluminium flashing details, for example. And there might be substrates with high moisture content, a freshly poured slab or screed where say the moisture content or the humidity or bare slab is too high to apply membrane.

So always check the TDS of the membrane that you've selected or the templates and then blank because it will essentially guide you as to what primer you want to use. On the right-hand side there, you can see that image of where you've got the porous and the non-porous substrate, it's a really quick and easy test to do, you can do it with a simple drop of water, drop it onto the surface it absorbs is a porous surface, if it's not absorbed, it's a non-porous surface. And that will then tell you Okay, do I need to use primer A or primer B, or trying to be if in doubt whatsoever? Or if it's a new type of substrate that we've not seen, you can engage Bostik, and we can do what's called a PATS test. PATS stands for pre-adhesion to the substrate. And we do these on a daily basis for a number of applications.

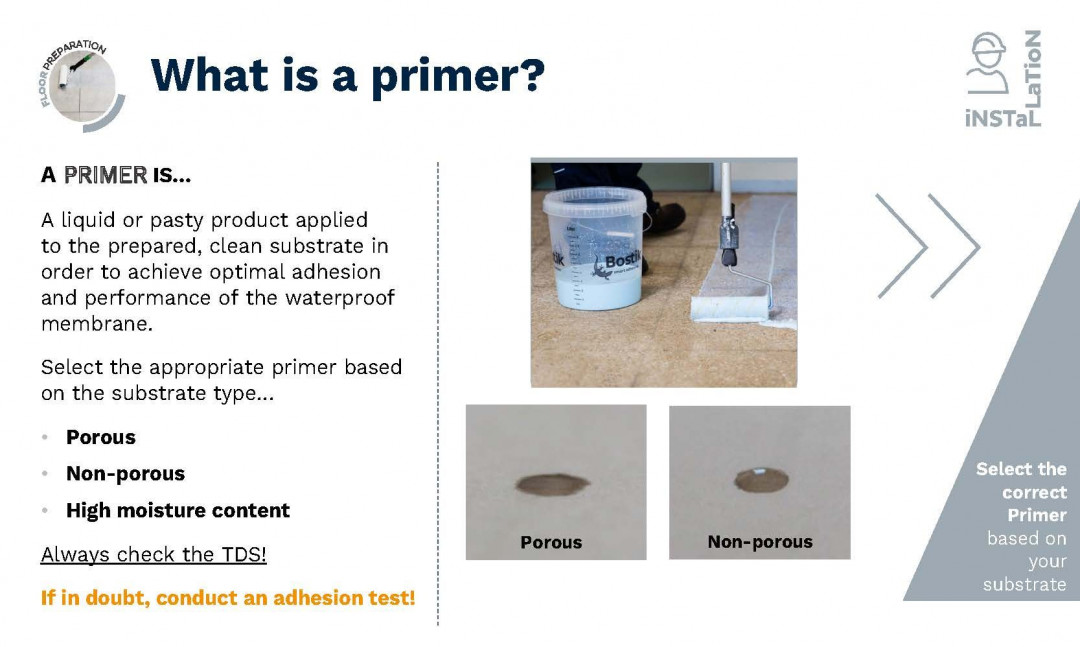

There's just an example there of to Dincel panel which I'm sure most of you would have heard of, which is like a preformed sacrificial formwork made of PVC and obviously, PVC being plastic can be quite difficult to bond tubes. So this is just an internal document that we've pulled together just to confirm what systems should Dincel panels be used as part of a building envelope.

So, some of the properties and characteristics of primers depend on the product,

They can penetrate porous surfaces, concrete for example, they can regulate porosity and consolidate dust. So, if a product if the surface is overly porous it can actually withdraw some moisture from the membrane that has been applied prematurely and make it hard to work. So priming regulates that surface you get a good flow out there membrane and consolidates any dust on the surface you're not getting adhesion issues, non-porous primers will provide grip on blocked surfaces or non-porous surfaces and certain moisture barrier primers will allow application on to dense substrates.

So, the advantages that they provide are they improve the overall performance of the membrane system essentially and ensure adhesion to those types of substrates. They can reduce pin holding as well. Pin holding is caused say by excess moisture in the substrate which on a warmer particularly prevalent in external applications. If the sun hits a balcony, and the balcony is damp the concrete stamp that sub that moisture will turn to vapour and it will try to drive out of that concrete. So what you want to do is suppress that by using a moisture barrier and that's the role that it plays and it just essentially improves the consistency of the surface which will then allow you to get the best out of the membrane.

So which Primer do you need? I'll just take you through some of the Bostik primers now.

Bostik multi-prime is our go-to general-purpose primer for porous substrates. Really easy to use and comes in a large size there are things 20 litres are water-based. It's usually about it's used with our membranes are tight adhesives for a wide range of applications and it provides adhesion for porous substrates just as commonly Pre render fibre cement sheath cable for example. And even timber in some instances, but it really good go-to solution issues with a wide range of our products

Then we move on to the N40 primer. So, the N40 primer is our go for any non-porous surfaces. So, non-porous being things like rigid plastics like UPVC, and ABS in some metallic substrates typical surfaces that you might find in a bathroom for example, if you've got a puddle flange, for example with a button where your outlets are going to go, what people are in aluminium flashing where your water stop is, for example, there are perfect examples of where you would utilise the importing primer prior to using one of our membrane systems. And it's simple to cloth method, wipe it on wipe it off, it cleans, it Prime's a surface, and you're ready to apply the membrane system.

We also have a go-to nonporous primer for our cementitious products, as well not forgetting that our membranes are often used with our toiletries if so we've got a product called drying grip as well. And what that does, is it provides adhesion to a non-porous surface for SM and tissue products. So our tile adhesives, our screeds, our levelling mortars, and it kind of falls into the same category.

We then have a product which is called a specialist primer, which is quite unique and we use this on a lot of approved applications. Only approved applications might be over Dampfix® PU, then fixed PU is our moisture-cured polyurethane, which is typically difficult to bond to, however, we've developed this primer which will then allow you to kind of overlay a water-based membrane, which is quite common, we use a more secure PU in the tray and water-based up the wall for bonding reasons. And so what we do is specialist primary is that promote adhesion at that junction where the floor meets the wall. And that allows us to offer a warranty system in those applications. It can also be used to promote adhesion to surfaces like the insole, again, where you've got a rigid plastic that is difficult to bond to, especially as primer can promote adhesion in those applications. So again, this is what we kind of steer towards approved applications only but very much a go-to in those difficult situations.

And then lastly, we've got the Moisture seal, which is our two-part epoxy moisture vapour barrier. And this is used in two ways. First of all, it's used as an against closing and a moisture vapour barrier. So our limits are 5.5%. So if the moisture content is greater than 5.5%, or the relative humidity is greater than 75%, then we recommend using a moisture seal. What that does is it kind of mitigates that moisture drives from the substrate and allows you to put the membrane down over the top, it might be early on a green screen, it might be early on to say onto a green slab, for example. Because if you weren't to use a moisture barrier, that vapour would simply blow the membrane off and get blisters and all kinds of issues. It also acts as the priming system for Dampfix® PU as well. So Dampfix® PU again is the moisture-cured polyurethane and this is the recommended priming system for that.

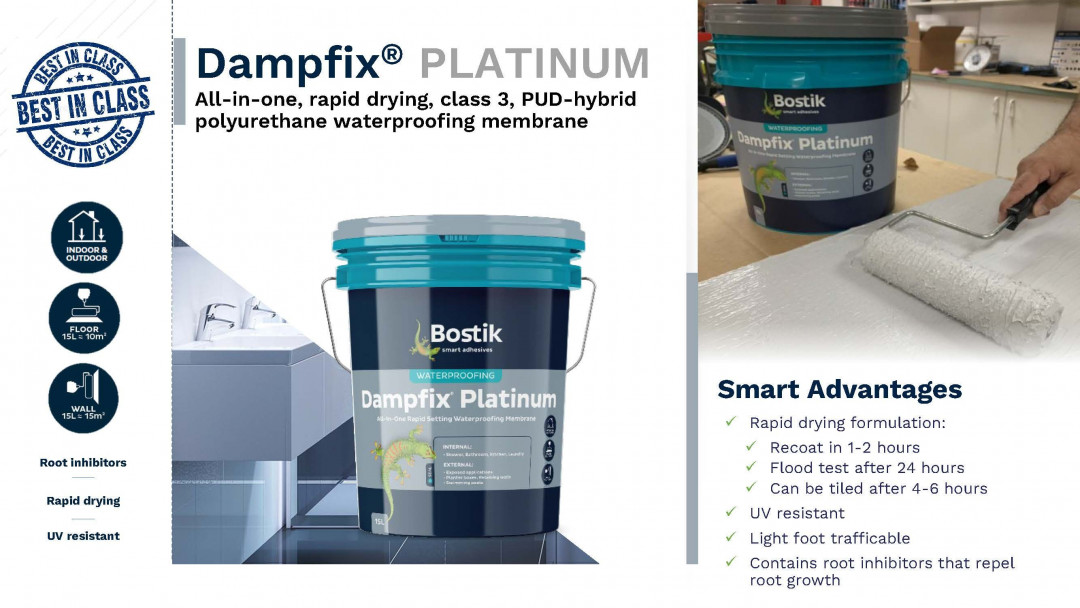

Bit of a focus now we've touched on the priming systems, I want to highlight our newest and greatest membrane system which is Dampfix® platinum, which you know, we've had Dampfix® installed in our range for many years now.

But platinum kind of sets that one level above exam premium all-in-one membrane system and I'll run through the all-in-one in a bit more detail now. So it's a rapid drying system. So time is money as we all know and schedules are getting shorter and shorter. So using a product like Dampfix® Platinum really kind of helps work towards that. Reducing the timeframes of application to be in a fast drying it could be recoated in one to two hours of flood testing after 24 hours. So it really kind of helps speed up that schedule when waterproofing internal areas for example. It's a class three membrane so high level of elasticity when tested to 48/58, which means bond breaking is simply either a hybrid sealant in the junction to a virtual coach fill it or you can use one of our bandage systems.

It can be tiled after four to six hours or so it'd be using one of our Bostik adhesives, so it really does offer that kind of rapid solution that is UV resistant also. So this is now being used throughout commercial applications on roof applications where there's limited traffic maintenance only which is more commonly the case. Dampfix® platinum is ideal for those applications to coast on an exposed roof and he's got high levels of abrasion resistance that can be left exposed in those areas and except for like for tropical so it also contains a root inhibitor as well so it can be used in subterranean applications it can also be used in swimming pools but if you're using it in planter boxes for example, it comes with the relevant certification that will demonstrate that should roots try and make his way down to the membrane trying to find a source of water that those inhibitors will prevent trying to penetrate the membrane itself, it won't damage the plant life it will just politely suggested goes that goes the other way.

So, just to kind of sum up where platinum can be used again is all in one system, so it can be used pretty much everywhere. So in terms of wet areas, so bathrooms, laundries for example, balconies and terraces, either exposed, it can be used as you can see down the top on the top image in a pedestal paver situation or we can actually be directly 12 in those areas also exposed rooftops but he touched on before commercial kitchens under tiles, swimming pools as well. So swimming pools can be used which is a fantastic sort of feather in the cap, but again needs to be covered by tiles. retaining walls, also, again, suitable for those kinds of below-ground areas where there's constant. moisture present always needs to be protected when you're backfilling. Like any membrane, but suitable for those areas. And as I touched on before, planter boxes, are also so the other thing to consider is if it's independently been tested and certified. So long gone are the days of using the technical datasheet. To demonstrate compliance platinum has been tested locally by Nata accredited laboratories, and it's an approved system so happy to share any certifications with you should you have an application we may be thinking platinum might be an option.

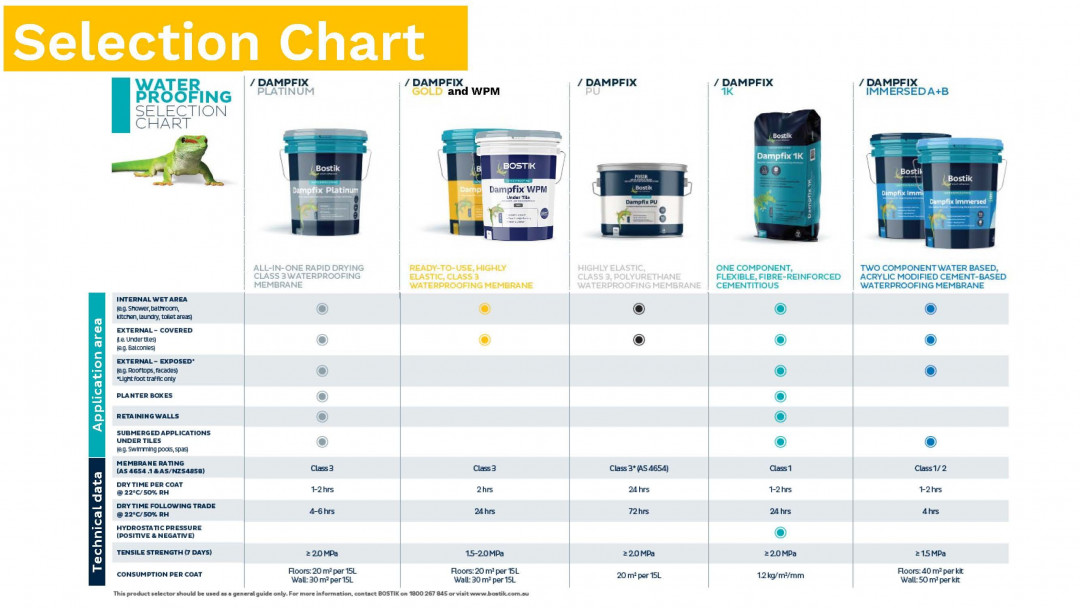

So where platinum sits within the Dampfix® range, you can kind of see here this is a bit of a spread of our membranes. And so Platinum sits here on the left-hand side as you can see, ticks all the boxes versus Dampfix® Gold and WPM, which is limited to protected applications only. So, under tiles or protected by pavers. Then you've got Dampfix® PU, which is a more secure or solvent-based Polyurethane, and then we've got Dampfix® 1K, which is a single-part cementitious membrane, particularly for belowground applications. And this is unique in the range that it can accept positive and negative waterproofing. So, if it was on a basement wall, you can apply it on the external side where the water sources are on the internal side of the wall on the other side of it, where the opposite side of the water source is. And then lastly, we've got them fixed immersed, which is our two parts cementitious, Part A and Part B, and you've got a highly flexible cementitious membrane. So, there's not much we can't do with this particular range.

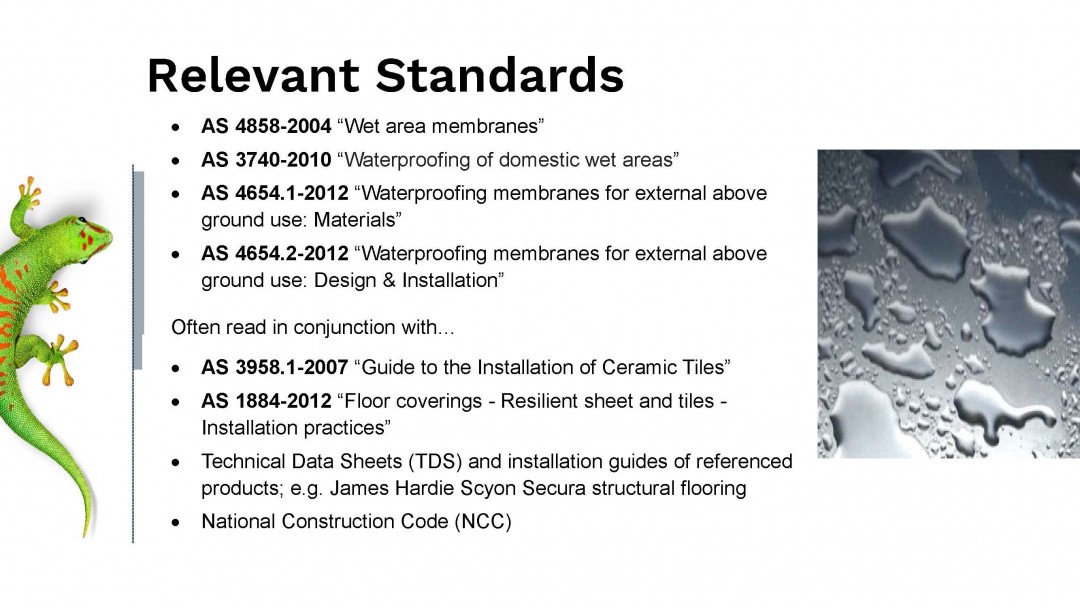

But as I mentioned earlier on, we always worked within the realms of our technical data sheets, and the Australian standards, as you can see here, so these you would have no doubt worked within or too many, many times over the years. But 4858, which is basically details of performance requirements are wet area membranes, so again, our membranes will be tested to that standard. And then 37400 sets out those installation requirements when using those earlier membranes, that's recently been superseded, there's a new version, which is 3740 2021 and that will be adopted when the new NCC lands in the new construction code are adopted, May 1st and so there's a whole other discussion that comes as part of that. And then we've got 4654, which is the external standard.

So that's the requirement for membranes to be used above ground. So on roofs, terraces, and balconies, no types of applications. And then part two of their standard details, how we install those, and that will again, set out the detailing requirements and things to consider when applying membranes externally. And then if you do an internal applications or external, these other standards, you know, which compliment the membrane. So this 3958, outlines the installation of ceramic tiles, and there's 1884 which details how you install resilient or soft flooring over the top. So it's not just a case of just focusing on the membrane. Sometimes we have to look beyond that and get guidance from other standards just to make sure that system that we're proposing meets the relevant requirements. And we always suggest reading these in conjunction with any other suppliers that might form are of that particular building element. And what we see quite regularly is lightweight balconies where there might be compressed by the cement structural flooring being used on say, a lightweight balcony.

It's essential that we read those guidelines in conjunction with our recommendations because there are strict requirements on say if you're bonding tiles versus putting a float-in screen over the top as to how you install the boards on a balcony. And this is something that we do as part of our specifications, we will raise that early in the document and say, look, it should be read in conjunction with, you know, Document A, B, and C. But again, it's just about, you know, looking beyond what's in front of us, and trying to take in all the requirements so that we get the best outcome at the end of the day. And obviously, the overarching requirement is the National Construction Code and we all work within that and all of that, and we should hopefully get a compliant outcome.

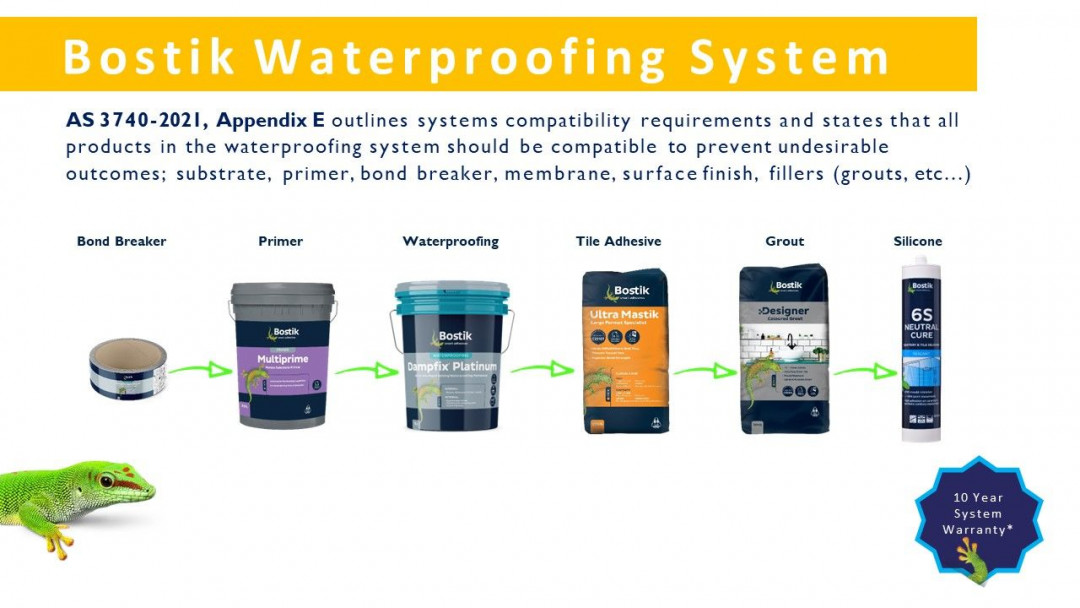

And then lastly, what I've touched on just now, the introduction of the new ISP simple zero, which is the wet area installation guidelines, within the new standard, what I wanted to highlight was Appendix E, and this is a new edition. And what this does is it outlines system compatibility, and the requirement and system capacity requirements, and he states that all products in the system should be compatible, and they should be a compatibility trail, so to speak, to sort of prevent, you know, any undesirable outcomes. So, it needs to be demonstrated as the substrate, the primer, the bond breaker being used the membrane, the surface, the finish, the adhesive, and any fillers, any kind of grouts or silicones, are all compatible. And what this does is it steers you towards a single point of supply because it happens quite regularly out on site where there's a requirement for you know, have you got an adhesive that, you know, can be used over this membrane, and chances are it will work based on the technology.

But moving forward, this is going to mean, we have to do adhesion testing, we'll have to get a non-plastic membrane being used, we'd have to be tested, or if it's a non-Bostik adhesive to be applied over Dampfix® is going to have to be tested. Now we're fortunate that we've got that capability. But it would make everyone's life easier in the long run if we kind of aim for that single point of supply. And there's something that we can support, we build out not just specification services, but the R&D side, providing testing to demonstrate compliance.

So, when we're talking about the waterproofing solution, I'll maybe talk about platinum. This is essentially the range, we've got the waterproof membrane, which is Dampfix® platinum. And then we've got our bond-breaking solutions there so we can offer you a sealant bond breaker, a bandage which is impregnated into the membrane itself all we've got a peel and stick bandage as well, which just all works towards speeding up that installation and just maybe in meeting product timings which is getting tighter and tighter every day.

So to sum up their discussion, hopefully, there's a bit of information in there and appreciate the opportunity to maybe expand on this post the seminar but Bostik Australia so we have a proven local manufacturer of high-performance waterproofing products, including not just Dampfix® platinum, but all the other Dampfix® products that form part of the range. Our primary systems can accommodate almost all substrates and situations and should there be any unknowns or new substrates brought into the marketplace, we had the capability to conduct PATS testing so the pre-adhesion to substrate testing to identify what the best solution is, for all your application. All our membranes are compatible with our tiler adhesives, which is critical to Appendix D are being used standard and we can provide testing to demonstrate that our membranes are all independently tested as well to demonstrate compliance to the relevant standards, at least all of which can be supplied as and when required.

What I'd like to leave you with the message is you know, don't risk it, Dampfix® it. Contact Bostik, we're here to support you, we're here to offer solutions and guide you in those areas and provide you with some solutions which meet all the requirements to provide you with that peace of mind that you've got a system that's going to perform long term.

Thank you very much for your time. I would like to put it out to the group now for any questions that you may have.

Indonesia

Indonesia

New Zealand

New Zealand

Philippines

Philippines

Hongkong

Hongkong

Singapore

Singapore

Malaysia

Malaysia