-

Australia

Copyright © 2024 Powered by BCI Media Group Pty Ltd

Get in Touch

Confirm Submission

Are you sure want to adding all Products to your Library?

Contact Detail

Whether you’re a professional woodworker, a hobbyist, or you’re interested in learning about the different types of woodworking joints so you can work on a DIY project at home, the more you understand about wood joinery, the better.

Each joint has its own specific strengths and advantages. When you are well-versed in woodworking joints, you’ll have a clear idea of which joints are best suited for the project you’re working on.

What is wood joinery?

In woodworking, to connect one piece of wood with another, you’ll use a joint. Some joints are basic connections that even a beginner can use. Others involve interlocking slots and are a little more difficult to work with, let alone to create.

How are wood joints held together?

You can connect the joinery with wood glue, brackets and screws, nails, dowels or staples. Keep in mind, the stronger the external connective force, the stronger the hold. So, if the type of joinery you’re using isn’t that stable, be sure to use a high-quality wood glue or connect the joinery with nails and brackets when possible.

What is the strongest woodworking joint?

For excellent stability, the mortise and tenon joint is a great choice. It’s a relatively simple joint, yet it holds well. Woodworkers have been using it for generations because of its strength, versatility and simple design.

Which type of wood joinery should you use?

Here’s a look at the most widely used joints you’ll find in woodworking and why you may want to use them.

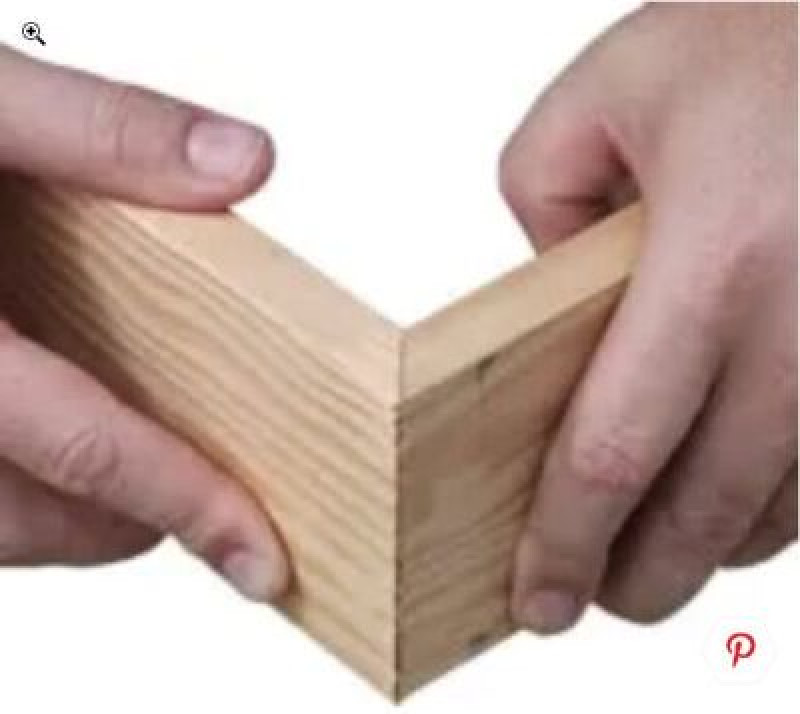

Butt joint

The butt joint is the easiest type to make, but it’s also one of the weakest. It’s a simple wood joint that anyone can use, and you’ll find it in a variety of woodworking projects including furniture and raised garden beds.

To make a butt joint, fasten the end grain of one piece of wood with the long grain of another at a right angle, lining up the wood evenly. You can glue the pieces together and then reinforce the joint with screws or nails. Hammer your nails into the face of one board so they drive through the grain of the other.

Butt joints also work well with dowels – drill the corresponding holes into the wood pieces using a dowel jig and insert the dowels with glue.

Mitred butt joint

Instead of connecting two boards at a 90-degree angle, with a mitred butt joint, one or both ends are mitred to a 45-degree angle, creating an angled corner. You can then fasten the boards together with nails or screws. You'll find this type of joinery used with exposed beams.

Dado joint

With this type of joinery, there’s a single slot cut into the surface of one piece of wood so the other piece will fit perfectly within the slot. If you’re cutting the slot, cut it perpendicular to the wood grain. The dado slot can either travel all the way to the other end of the wood board or it can stop before the edge.

Dado joints are often used for bookcases, cabinets or dressers. You’d use the dado joint where the back and the side of the bookcase or other piece of furniture connects.

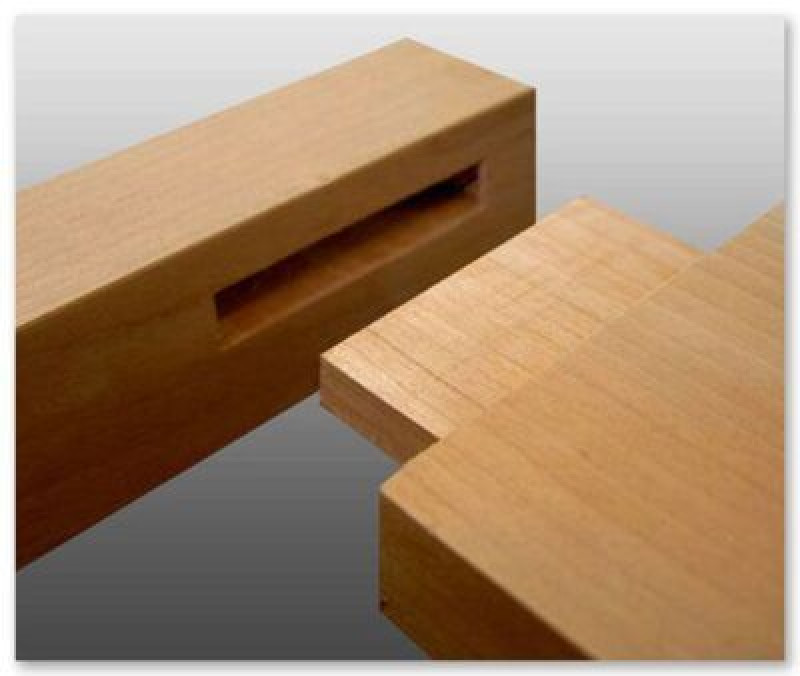

Mortise and tenon joint

This is one of the most traditional types of woodworking joints. It involves a mortise, which is a rectangular or square-shaped hole or cavity carved into the side of one board, and a tenon. The tenon is a protruding piece on the other board, which is the same size as the mortise.

Generally, the tenon should be about one-third the thickness of the piece of wood. Whilst you’ll need to make sure the mortise and tenon are the right size to create a perfect fit, this type of woodworking joinery looks elegant once it’s in place because you don’t need to use any nails or screws.

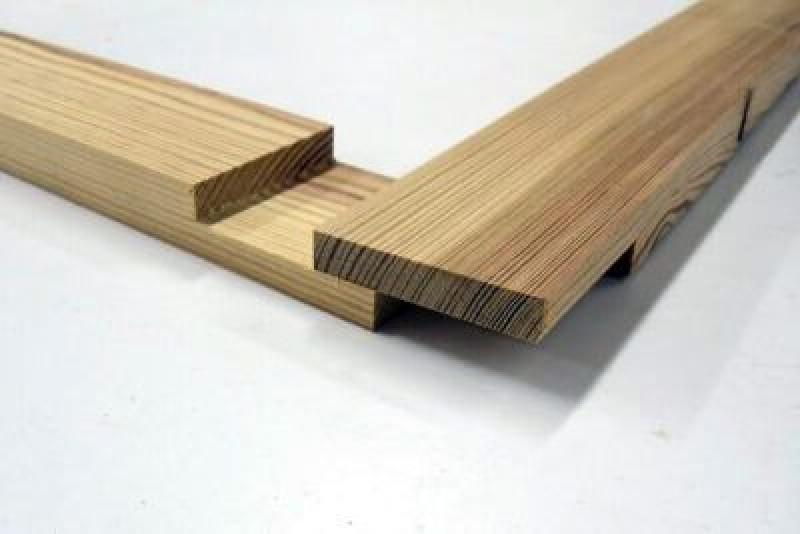

Half lap joint

With a half lap wood joint, half of the thickness of each piece of wood is removed. When you fasten the boards with glue, they should fit together seamlessly just as a puzzle piece wood. This is a great joint to use when the wood pieces you’re using have the same thickness. Lap joint uses include building storage furniture or desks.

You can also use variations of the lap joint.

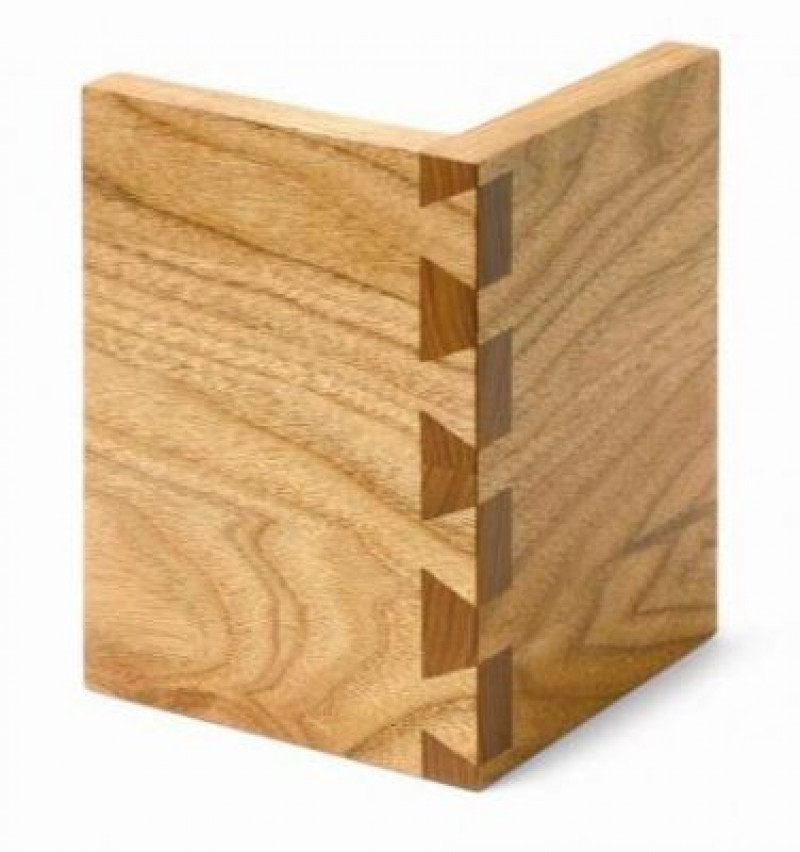

Dovetail joint

The dovetail joint is often used in advanced woodworking projects because of its inherent strength and aesthetic advantages. With this type of joinery, notches are created to fit the boards together. When it’s done, it looks like the wood tails and pins are interwoven together.

You can use this woodworking joint for wooden boxes and drawers. You’ll only need glue to bond the pieces together tightly because the joint itself is so stable.

Tongue and groove joint

With this type of joint, the edge of one board has a grooved notch that extends beyond the edge of the board. Then the edge of the joining board has an extended thin tongue that will fit within the groove of the housing board. Once the boards are laid together, they lock into place. This type of joint is often used for laying floating timber flooring or laminate floors.

How to get the best results from your woodworking project

Working with different woodworking joints can seem overwhelming at first, but as you start trying out different joinery types, you’ll get a better grasp for how each joint performs. And, it’s a lot of fun.

Once you pour your time and hard work into a project, you’ll want to protect the finished product. Whether you’re creating wooden cabinets, toys, furniture, decking or any other wood projects, you can preserve the wood for years with food-safe, toy-safe, and pet-safe hardwax oils from Whittle Waxes.

Made from a blend of sustainable natural ingredients, hardwax oils can enhance the aesthetic of your woodworking whilst protecting the wood from stains, warping and scratches. Browse Whittle Waxes Hardwax Oils range to learn more.