-

Australia

Copyright © 2026 Powered by BCI Media Group Pty Ltd

Confirm Submission

Are you sure want to adding all Products to your Library?

Contact Detail

13 Oct 2022 by Construction Specialties

Construction Specialties says it’s time to end ‘opt-in’ building product safety standards

With confidence in the building sector at an all-time low, Construction Specialties is calling for the full-scale corner room burn test to be standard on all surface building products.

“On the fifth anniversary of the Grenfell Tower fires, and the Australian building sector under increasing scrutiny, the stakes have never been higher to get it right,” says Bill Maloukis, General Manager of Construction Specialties in Australia.

“Australians deserve more than ‘calculations’ and ‘guesswork’ when it comes to how a product will fare in a fire. Full-scale corner room burn tests give the industry, and our citizens, the confidence they need,” he said.

Fire Safety Engineer, Christina Knorr agrees. “While the Building Code of Australia allows for the use of the small-scale cone calorimeter testing, it comes with limitations. It really should be considered as pilot testing in preparation to the large-scale test. The full-scale test provides a live scenario and an opportunity to see the performance of the product in its real application,” Knorr says.

When internal lining products are involved in a fire, the speed of fire spread, and the rate of smoke production impacts the ability of the building occupants to evacuate.

“Linings that have not been tested or those with a non-compliant Group Number may result in untenable conditions before the building occupants can reach a place of safety,” she added.

Construction Specialties made the decision at the end of last year to put its Acrovyn® 4000 products to the test – and it paid off.

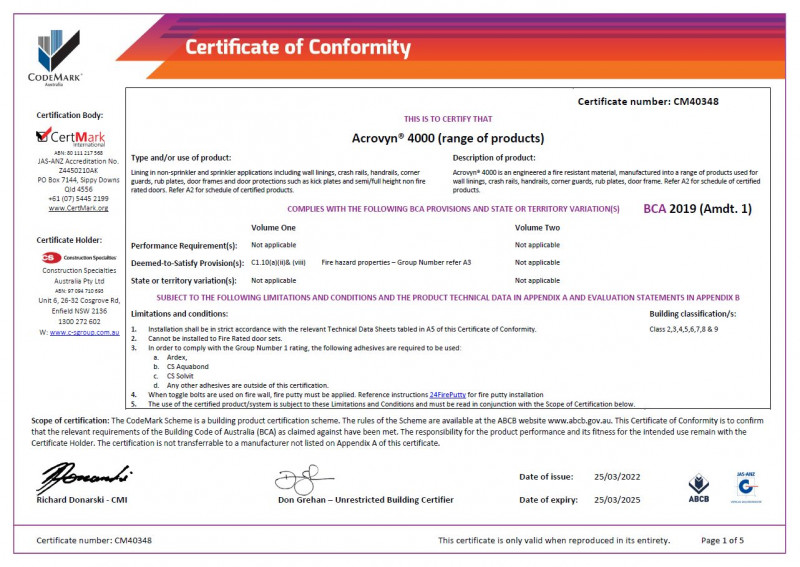

“Our Acrovyn® 4000 products now have CodeMark® accreditation. We always knew they excelled in fire and accessibility compliance, but the CodeMark proves it,” says Mr Maloukis.

Acrovyn® 4000 is a PVC-free engineered fire-resistant material, manufactured into a range of products used for wall linings, crash rails, handrails, corner guards, run plates and door frames.

Popular in high traffic areas such as lobbies, reception areas and lifts, as well as food courts and play centres, Acrovyn® 4000 can be found in hospitals, retail, hotels, education facilities and workplaces. It is a key design feature, ensuring longevity of a building’s interior, while helping to reduce maintenance costs and the need for repairs and redecoration.

To achieve its CodeMark accreditation, Acrovyn® 4000 was put through its paces in a full-scale corner room burn test. The test was used to investigate the potential fire spread, smoke density and the heat release rate of a surface lining product when exposed to fire (AS ISO 9705-2003). Acrovyn® 4000 obtained a Group 1 fire compliance rating – the highest possible.

Mr Maloukis says the corner room burn test is far superior to the small-scale cone calorimeter test, in which just a small sample is tested (and not tested in the context of its application i.e., affixed to walls).

“Trust is currency in the building industry. CodeMark accreditation sends a clear message to our customers: that extensive testing has been conducted and compliance has been proven,” he said.

Acrovyn® 4000 is the first PVC-free wall protection product to achieve CodeMark accreditation in Australia.

“All parts of the construction industry – from architects to builders to trades – want to make sure they’re getting it right, whether it’s the best materials for the job, or reliable suppliers. Navigating materials certification can be a time intensive and high-stakes task, and Construction Specialties wants our customers to have as much faith in our products as we do.”

“Achieving CodeMark accreditation for our entire range of Acrovyn® 4000 products is more than just a stamp-of-approval – it gives our customers peace of mind that Acrovyn® is the right product for the job,” concludes Mr Maloukis.

Construction Specialties is pursuing CodeMark accreditation on all its products that fill vital roles in critical areas of a building.