-

Australia

Copyright © 2026 Powered by BCI Media Group Pty Ltd

Confirm Submission

Are you sure want to adding all Products to your Library?

Contact Detail

23 Aug 2021 by Network Architectural | Facade & Ceiling Solutions

White Paper on

ALPOLIC™ NC / ALPOLIC™ A1 Non-Combustible Cladding

prepared by ExcelPlas Materials Testing & Cladding Test

Introduction:

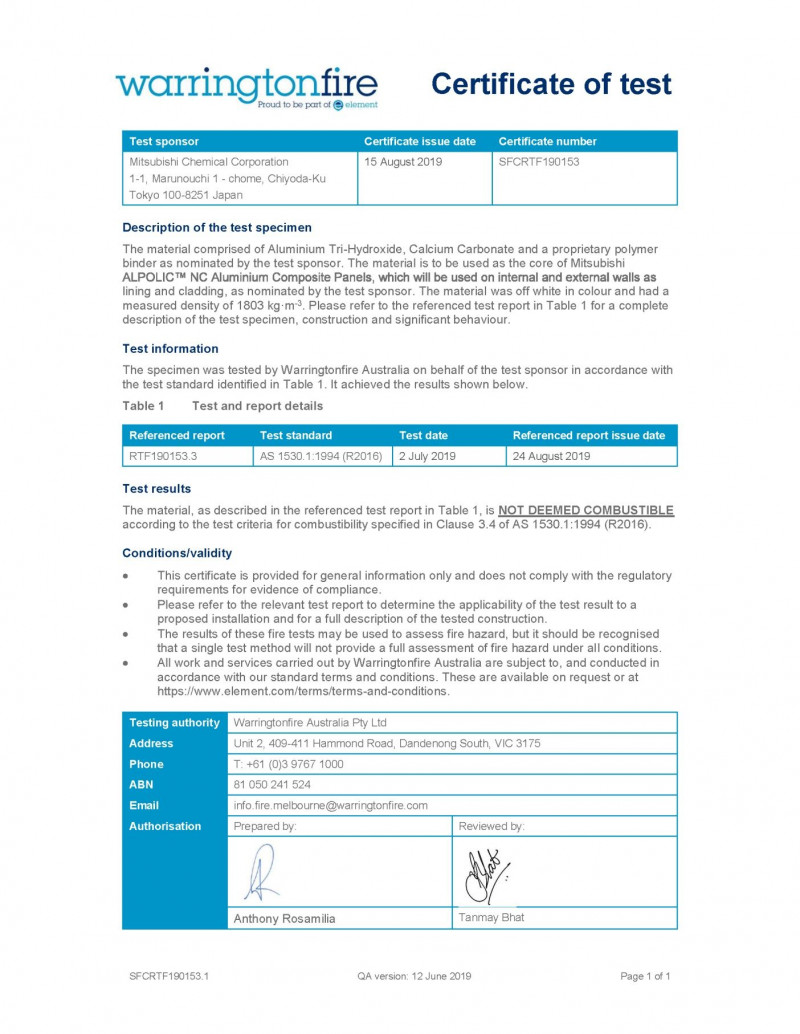

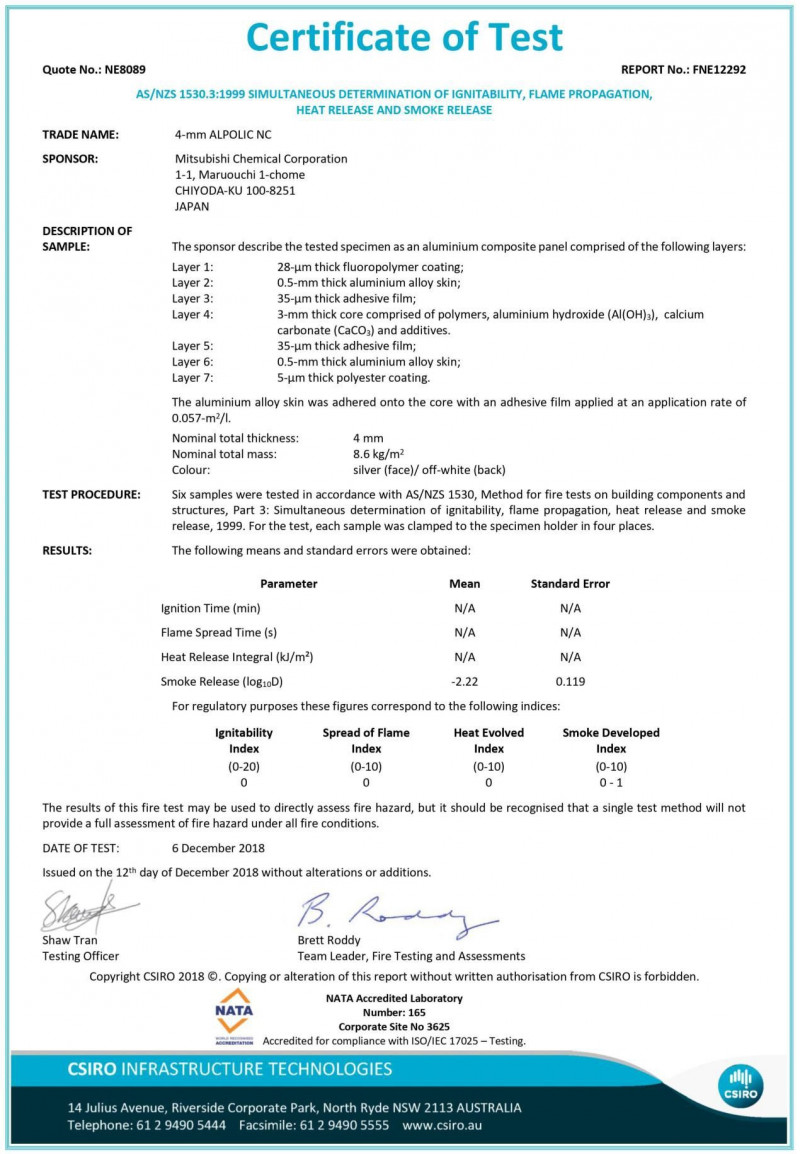

This White Paper discusses the test results and performance data of ALPOLIC™NC / A1Non-Combustible CompositeCladding manufactured by Mitsubishi Chemical InfratecCo., Ltd In Japan.

Independent testing and analysis has been performed by NATA-Certified ExcelPlasLabs who are specialists in the compositional analysis and testing of polymers and polymer composites.

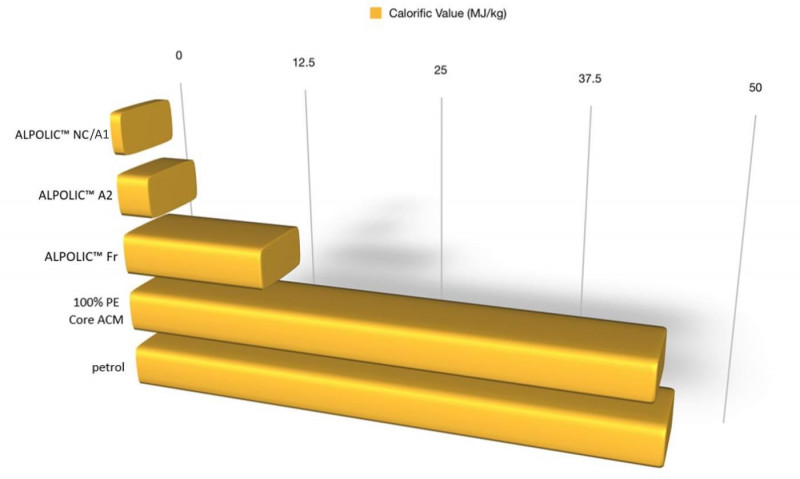

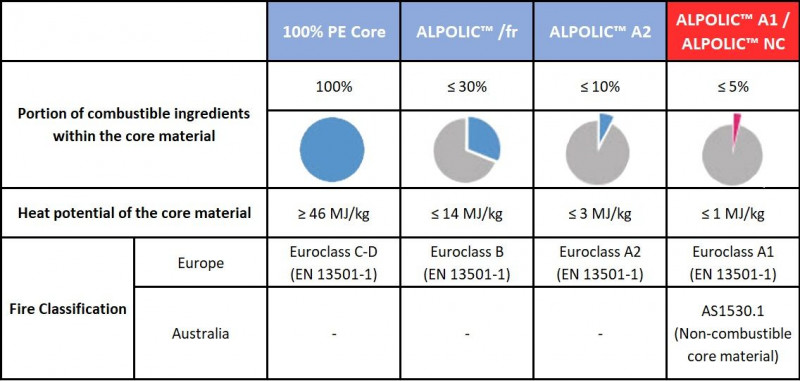

Independent ExcelPlastesting has shown that ALPOLIC™NC/A1 has a non-combustible mineral core containing less than 5% polymer and greater than 95% inert filler (inert content) by mass.

ALPOLIC™NC/A1 is a CodemarkCertified non-combustible material fully complying with the DtSprovisions as per NCC/BCA and can be used as external wall cladding in new buildings and retrofit applications wherever a non-combustible material is required.

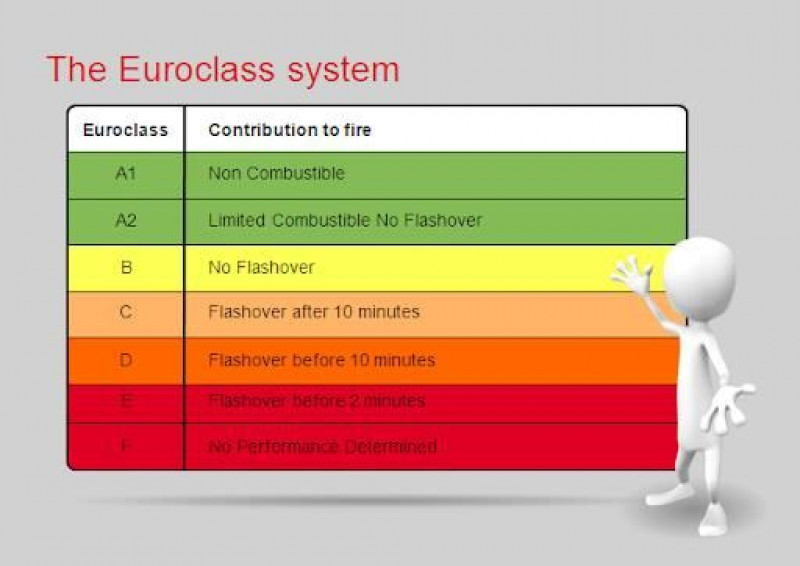

Additionally, this material has also obtained the A1 Classification when tested in accordance with EN13501-1, which is a milestone for an ACP to pass this criteria.

ALPOLIC™NC/A1 core is also certified non-combustible when tested in accordance with BS476 Part 4.

ALPOLIC™NC/A1 is the only ACP with a non-combustible mineral core in Australia that achieves the highest possible safety rating (Category D) with the Insurance Council of Australia.

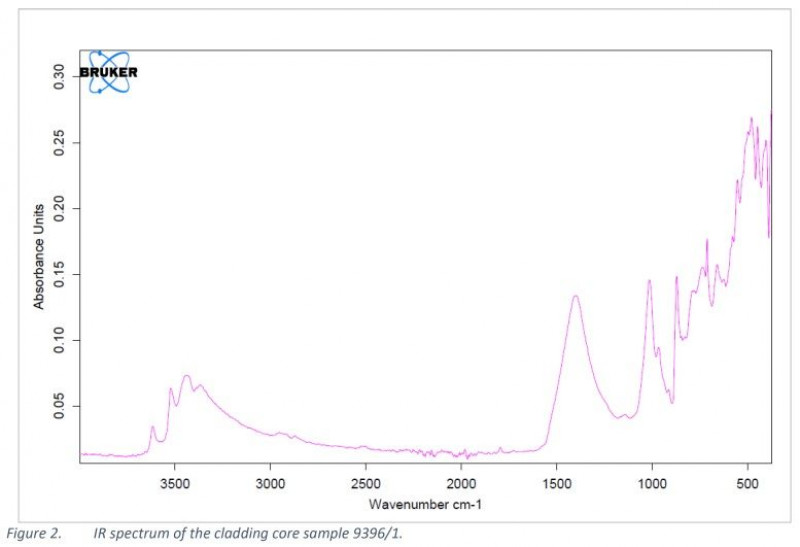

Fourier Infra-red Spectroscopy

(FTIR) testing of mineral

components in

ALPOLIC™ NC/A1 Cladding

ALPOLIC™ NC/A1 has ZERO polyethene as tested at ExcelPlas, one of the few official laboratories in Australia which are recommended by the Insurance Council of Australia

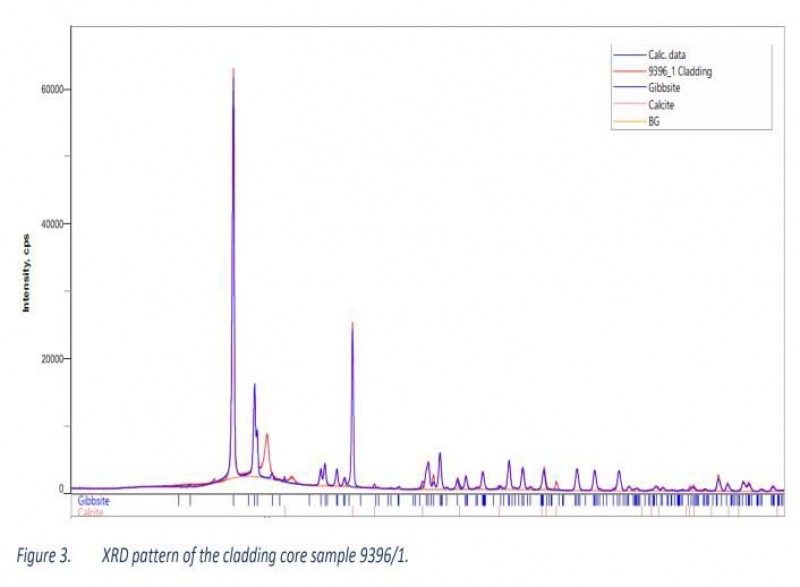

X-Ray Diffraction (XRD) testing of mineral components in ALPOLIC™ NC/A1 Cladding.

Gibbsite –Aluminum Tri-hydrate Calcite –Calcium Carbonate

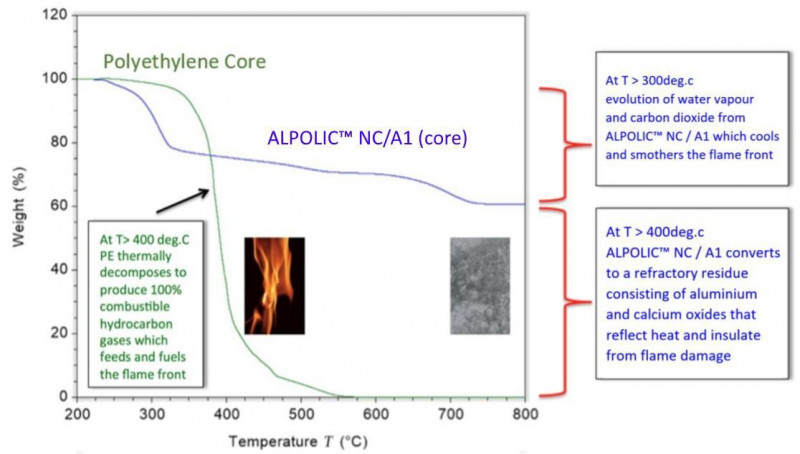

Thermogravimetry (TGA) testing of mineral components in ALPOLIC™ NC/A1.

ALPOLIC™NC / A1 –Deemed non-combustible to BCA 2019

This is in compliance with Clause C1.9(e)(vii) of the National Construction Code, specifically relating to the use of bonded laminated products wherever a non-combustible material is required:

ALPOLIC™NC / A1 Technical Note on Adhesive Layer April 2020

Following the announcement by Mitsubishi Chemical Corporation on January 14, 2020 that ALPOLIC NC has passed the European Fire Standard “EuroclassA1” tested in accordance with EN13501-1, therefore ALPOLIC™NC is now A1 Classified. This is the first ACM in the world to be certified under the EuroclassA1 standard, which is a milestone in ACM history. ALPOLIC™NC / A1 is a Deemed-to-Satisfy (DtS) panel which fully complies with Clause C1.9(e)(vii) of the National Construction Code.

While there are products that have claimed to be DtS under Clause C1.9(e)(vii) of the National Construction Code, the adhesive layer in ALPOLIC™NC / A1 is less than 0.05 mm in thickness on each side and total thickness of adhesive layer is less than 0.10 mm.

ALPOLIC™NC / A1 is the first ACM under Category D (non-combustible) in the Insurance Council of Australia Hazard Identification and Category Rating Guide, which is the BEST possible rating;

ALPOLICTMNC / A1 offers higher performance than solid aluminium cladding in the following ways:

Mitsubishi ALPOLICTMNC / A1 offers higher performance than solid aluminium cladding in the following ways:

Glossary of Terms

About ExcelPlas:With more than 25 years’ experience, ExcelPlas is acknowledged as a leading provider of specialist analytical and technical capabilities for the building and construction industry in the area of polymer analysis. ExcelPlas Labs use a range of analytical techniques to assist building owners, building managers, building insurers, fire engineers and other stakeholders to provide advice relating to the flammability potential, composition and toxicity of cladding materials. ExcelPlas is a NATA-accredited laboratory and is ISO/IEC 17025 compliant.